Activated Charcoal 2: Biomass Wastes as Carbon Precursors

Published Date: 18th January 2021

Introduction

Agricultural, and forestry activities produce large amounts of wastes or biomass residues from harvestable yields, with crop derived wastes accounting for 94 percent of global biomass production. The major crops comprise cereals (wheat, rice, maize, barley, sorghum, and millet), sugarcane, oil crops (soybean, sunflower, peanut, and oil palm), fruits, vegetables, roots, and tubers (cassava, cocoyam, potatoes, yam, etc.), coconut, date palm, pineapple, and bananas among others. A 2015 estimate by the United Nations Environment Programme (UNEP) reported that globally, 140 Gt of agricultural residues are generated each year, while the global resource from unexploited cereal crop residues alone was estimated at about 517 million tons. Lal in a more recent 2019 estimate, reported 2.8 Gt for cereal crops, 3.1 Gt for 17 major kinds of cereal, and legumes, and 3.8 Gt for 27 common food crops. Globally, an estimated 66 percent of the residual plant biomass comes from cereal straw, with over 60 percent of these residues being produced in developing low-income countries. Sugarcane wastes from the stems, and leaves are the second largest contributors, while residual biomass from oil crops, roots, and tubers, nuts, fruits, and vegetables are also important. The UNEP has projected that these residues will continue to increase with the global population, especially as efforts are made to increase food production through intensification of agriculture, and increased crop yield.

Forestry activities also generate woody wastes or biomass residues from timber logging, and non-timber forest activities. The International Energy Agency, (IEA) in 2012 estimated the global production of wood-derived biomass at about 4.6 Gt annually. Sixty percent of the wood-derived biomass is utilized in energy generation, while 20 percent are used as industrial ‘round wood’ and the remaining 20 percent are left in the forest as primary production wastes. Therefore, an estimated 80 percent of wood-derived biomass is lost as waste, with about 20 percent of the wood ending up in the form of a kiln-dried sawn product. Indeed, for every cubic meter of forest wood material removed, a cubic meter of waste is discarded in the forest, while the harvested log is processed to produce different wood products. The waste generated from this process such as initial branch trimming, and bark removal, slabs/blocks/further trimmings, and sawdust accounts for about 58 percent of the original log. After kiln drying, shavings, and sawdust/trimming are performed, another 8 percent of the log may also be lost as waste. However, residues such as stumps, branches, and leaves as well as processing wastes like logs, sawdust, and shavings generation, and recovery have been shown to depends on factors such as tree species, and local geographical conditions.

The United Nations categorizes, agricultural wastes as manure, and other wastes from farms, poultry houses, and slaughterhouses; harvest waste; fertilizer run-off from fields; pesticides that enter the water, air, or soils; salt, and silt drained from fields. The World Energy Council, also includes spoiled food wastes as part of agricultural wastes. According to Raschka and coauthors, the scientific definition of the term‚ biomass encompasses all organic substances of non-fossil origin such as all plant or phytomass, and natural living organisms (flora and fauna), the resultant residues (e.g. animal excrements), dead (but not yet fossilized) phytomass, and organic matter (e.g. straw) as well as all substances generated through their transformation by means of the application of technology and/or use of the material or substances that are the result of such a transformation (e.g. abattoir waste, organic household waste). Many crops often require further processing, and this process usually generates secondary, and tertiary waste streams in addition to the primary biomass wastes realized during field harvest. Although biomass wastes are consistent by-products from agricultural production in all regions of the world, their values have not been fully exploited in most developing countries where they are left in the field to decompose naturally or are openly burnt to make room for other activities.

Conventional uses of biomass residues

Biomass residues are cheap, and bulky materials that are generally environmentally benign, and therefore often returned to the soil as manure. Unused urban generated biomass residues may however constitute serious environmental problems when dumped in municipal landfills or burned to reduce their bulk. Biomass wastes are however cheap renewable resources, which are high in carbon content, and have been used in renewable energy, and the production of value-added products. The use of biomass waste to produce energy, and other products is currently of increasing interest to farmers. Their conversion into energy, and other products can reduce environmental problems, and generate value-added products, especially in countries where agricultural activities result in the generation of large quantities of biomass wastes. The primary use of biomass wastes in developing countries has been as a cheap energy source in open fires for cooking, and heating. Indeed, an estimated three billion people in developing countries rely on biomass-based fuels in the form of wood or charcoal for cooking, and heating. Household burning of biomass generates substantial amounts of ash, which traditionally has been returned to the land as an enrichment. However, biomass-based energy generation plants produce large volumes of ash that require regulatory control, and careful disposal, usually in landfills, in order to avoid environmental consequences.

Recent technological innovations have made the use of the plant, and animal biomass wastes for biogas generation possible, although this technology has not been readily adopted in Africa. Several reports however show that biogas plants commonly used for energy generation in commercial farms, processing units, and households in Asian and South American countries. Another biomass waste conservation approach that is also being promoted is their composting to produce organic manure similar to manures produced from the animal, and food wastes. Composting is the natural process of rotting or decomposition of organic matter by micro-organisms such as bacteria, fungi, actinomycetes, algae, and protozoa under controlled conditions, while vermicomposting is the same process aided by earthworms.

Biomass as a source of pyrogenic carbon

Perhaps one of the most viable approaches to biomass wastes conservation is their pyrolysis to generate pyrogenic carbons such as activated charcoal, and biochar. This has gained increasing attention because of the renewed global interest in applying charcoal, black carbon, and biochar as amendments to stabilize soil organic content. The approach has been researched extensively as a viable option to mitigate greenhouse gas emissions, while significantly reducing the volume of biomass wastes generated from both agricultural, and forest activities. Biomass contains an average of 50 percent carbon, which is rather rapidly decomposed, and reemitted to the atmosphere upon decay in the soil, with fresh biomass taking just from few months to years to decompose. When converted to biochar, between 10 and 70 percent of this carbon is retained, and slows down the rate of carbon decomposition by as much as centuries or even millennia. The pyrogenic carbons in the form of activated charcoal, and biochar are therefore long-term carbon sink, with very slow chemical transformation, suitable for soil amendment, by interacting with the soil matrix, soil microbes, and plant roots, thereby helping in nutrient retention, and other beneficial biogeochemical processes. These pyrogenic carbon materials are also increasingly used in water treatment, construction industry, food industry, cosmetic industry, metallurgy, and other chemical applications. Of interest also is their use as a feed additive for all classes of farmed animals. In most African countries, however, the activated charcoal, and biochar application in agriculture is limited even though their production is essentially a very simple technology. Based on their wide applicability, it may be more appropriate to promote the production, and utilization of activated charcoal, and biochar in Africa, and other developing countries.

Physicochemical nature of biomass wastes

Biomass residues are heterogeneous in their physical characteristics, especially in their bulk density, moisture content, particle size, and as influenced by the processing method applied. They are usually fibrous materials, low in nitrogen, and may vary according to geographical location. The chemical composition of any biomass residues is influenced by a number of factors among which may be species, age of residue, a period of harvest, the physical composition including the length of storage, and harvesting practices. Plant biomass is composed mostly of cellulose, hemicellulose, and lignin with minor amounts of pectin, protein extractives, sugars, and nitrogenous material, chlorophyll, and inorganic waste. Cellulose is however the most abundant organic polymer present in the cell wall of plant biomass, while hemicellulose surrounds the cellulose fibers, and stands as the connecting link between cellulose, and lignin. Lignin is mostly present in the outermost layer of the fibers, and has the chief function of imparting strength, and rigidity to the cell wall of the crop or woody biomass material by acting as a structural matrix. Lignin is almost impermeable, resists fermentation, and most chemical, and biological degradation processes. It is a three-dimensional phenolic polymer, and is responsible for the cementation of cellulose fibers in plants. Hemicelluloses, predominantly xylan, are non-cellulosic polysaccharides with comparable low molecular weight. The non-food-based portion of crops such as the stalks, straw, and husk are therefore characterized as lignocellulosic biomass. Woody biomass wastes are also largely composed of cellulose (40 to 55 percent by weight), hemicelluloses (mostly xylan in hardwoods, with 20 to 35 percent by weight), and lignin (18 to 35 percent by weight).

The compositional values of these lignocellulosic fractions (lignin, cellulose, and hemicellulose) in the biomass waste can be determined by wet chemistry by analyzing for the neutral detergent fibre, acid detergent fibre, and acid detergent lignin. The compositions of these fiber fractions in a given plant material will usually depend on the nature of the biomass, and the part of the plant. For example, leaves, and seed hair are low in lignin content, while cotton, coconut, and hazelnut shells have up to 48.7 and 51.3 percent of lignin contents respectively. Cellulose, hemicellulose, and lignin make up more than 90 percent of lignocellulosic biomass, and 80 percent of herbaceous biomass. The inorganic compounds, and metals in the biomass wastes are usually present in the form of ash, with the range being from less than 2 percent in softwoods, to as much as 15 percent in herbaceous biomass, and agricultural residues. The major metal constituents of biomass wastes are potassium, calcium, sodium, silicon, phosphorus, and chlorine. These are routinely determined by either atomic emission spectroscopy or plasma mass spectrometric methods.

Proximate analysis is performed to determine the four essential feedstock fractions namely moisture, a volatile matter which consists of the component of the biomass except for the water that is liberated as gases and vapors at high temperature in absence of oxygen, fixed carbon (the non-volatile fraction of biomass), and ash which is the inorganic residue that remains after combustion. Agricultural residues having high volatile matter values also record higher conversion in comparison to residues with high fixed carbon. Hence, biomass with a higher volatile fraction may be suitable for the production of bio-oil, while the one with higher fixed carbon may be suitable for the production of activated charcoal. The ultimate analysis test generates ampler information than the proximate analysis since it also determines the carbon, hydrogen, nitrogen, sulfur, and oxygen in the biomass material. Researchers at the Karlsruhe Institute of Technology, Germany, investigated the chemical properties of several biomass waste materials, and reported the following values on a percentage dry weight basis. Carbon content (39.6 - 50.7 percent), hydrogen (4.6 – 6.0 percent), oxygen (36.4 - 45.5 percent), nitrogen (0.5 – 1 percent), sulphur (0.1 – 0.2 percent), chloride (0.2 - 0.7 percent), ash (0.8 – 18.3 percent), and water (4.0 – 10.7 percent). Oh and coworkers also investigated the chemical properties of orange peels, residual wood, and water-treatment sludge used as feedstock material for biochar production, and reported variations in the most important elements. For example, the carbon contents were 41.85, 45.78, and 6.58 percent respectively; nitrogen contents were 0.99, 0.28, and 1.78 percent respectively; oxygen contents 47.93, 44.06, and 15.28 percent respectively, while hydrogen contents were 6.37, 6.11, and 1.78 percent respectively. The ratios of these elements however provide a better comparison among the feedstock, especially in determining the heating value. Chaniwala and Parikh developed an empirical correlation for the determination of the heating value of biomass using elemental and proximate analysis as shown below

HHV (MJ/kg) = 0.3491 (C) + 1.1783 (H) – 0.10 (S) – 0.0134 (O) – 0.0151 (N) - 0.0211 (A).

Volatile matters and fixed carbon contents of a biomass material influence its ignition, and gasification/oxidation characteristics. High volatile matter containing biomass wastes are more reactive, and volatilizes easily, thereby producing less char. High ash contents in the biomass reduce the energy content of the material proportionately. Again, during the thermochemical conversion process, the ash may create significant operational problems, such as the formation of slag from ash at elevated temperatures. Ash content range of 2 – 5.84 percent, has been reported to be suitable for combustion, and pyrolysis conversion processes.

Physical and thermo-chemical and compositional characterization of plant biomass is critical to their use as a precursor for activated charcoal production, because these properties significantly influence the biomass conversion process. The important physical and thermochemical properties include moisture content, high heating value, fixed carbon, volatile matters, ash/residue, alkali metal, and cellulose/lignin ratio. The compositions of cellulose, hemicellulose, lignin, and other extractives in biomass waste are also important because these are known to influence the conversion processes. For example, the higher the percentage of cellulose, and hemicellulose in the biomass, the higher the rate of thermal degradation during pyrolysis, due to their lower degradation temperatures. Similarly, cellulose, and lignin proportion in the biomass affects its carbon content, with higher lignin content resulting in the higher carbon content of the biomass-derived biochar or activated charcoal. Again, the cellulose, hemicellulose, and lignin content of the biomass waste influence its thermal behavior, since they decompose at distinct temperature spectrums during combustion. For example, the hemicellulose decomposes earliest during the combustion process, usually at the temperature range of 210 - 315oC, while cellulose decomposition happens at the temperature range of 315 - 400oC. Lignin requires higher temperatures, with its decomposition occurring slowly under a much wide temperature range (160 - 900oC). Thus, the higher percentage of cellulose, and hemicellulose in the biomass the higher the rate of thermal degradation during pyrolysis.

Comparison of the physicochemical nature of different types of biomass wastes

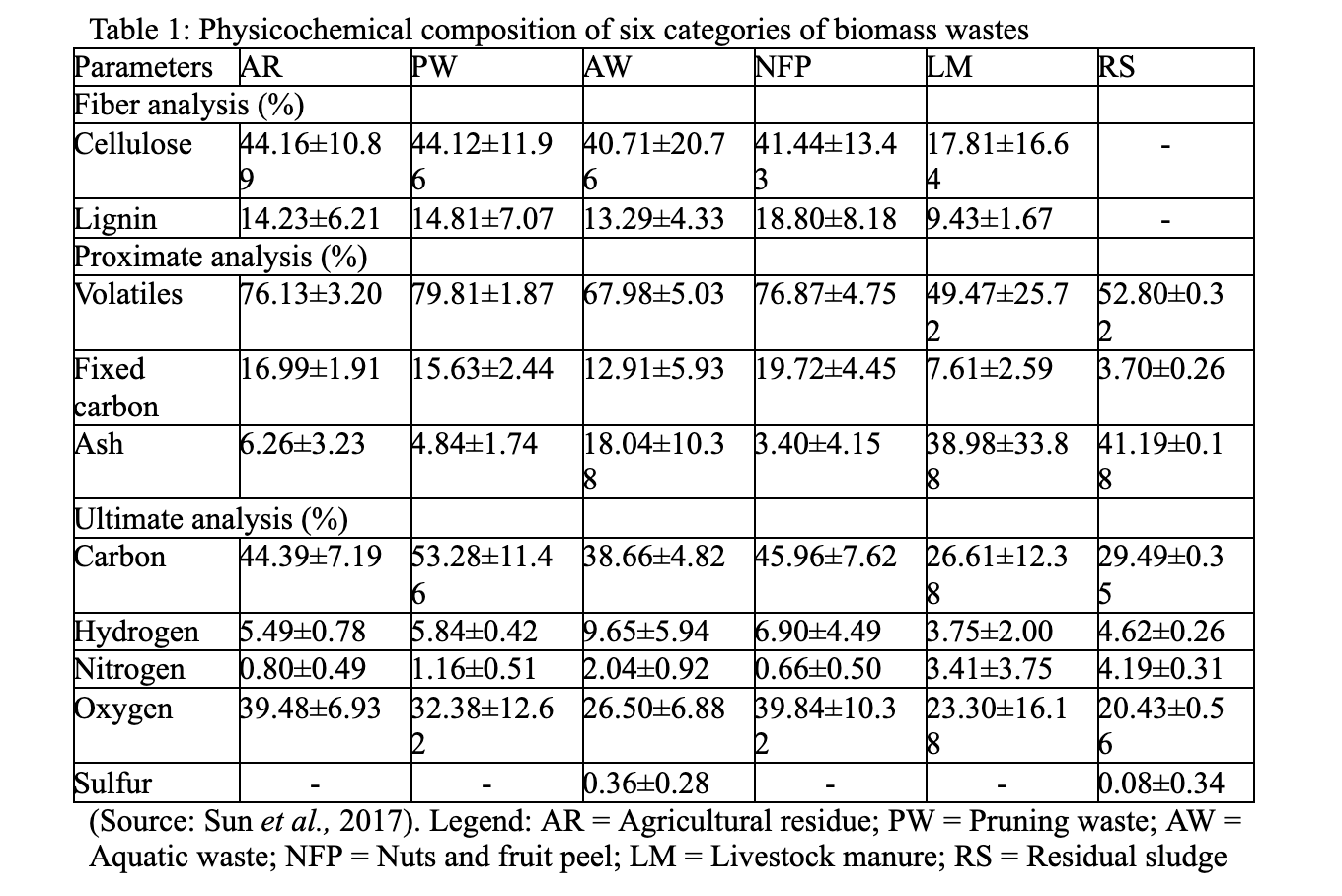

The physicochemical properties of biomass may vary widely among different plant species, and even within species, especially across plant parts, growing conditions, and harvest times. This variation also influences the properties of the pyrogenic carbons produced from these biomass materials. Biomass waste has therefore been classified into five categories according to source or origin to include woody biomass, agricultural residues, aquatic plant, human and animal waste, and industrial waste biomass. Researchers at the Qufu Normal University, Rizhao, China, assessed the physicochemical composition of 60 types of biomass wastes which they categorized into 6 groups, namely, agricultural residue, pruning waste, aquatic waste, nuts, and fruit peel, livestock manure, and residual sludge. Their results showed wide variations across the different categories (Table 1), with the residual sludge, and livestock manure recording higher ash contents, and lower organic constituent values than the plant-derived biomass categories. Among the plant biomass, aquatic waste recorded the highest ash, and lowest volatile matter contents, and also the highest overall hydrogen, nitrogen, and sulfur contents. Sulfur, and nitrogen contents were generally very low in the pruning wastes, and agricultural biomass categories. The yield, and characteristics of biochar derived from the different biomass were shown to have been influenced by the varied physicochemical nature of the biomass feedstock, as well as the pyrolysis conditions, and will determine the eventual application of such biochar.

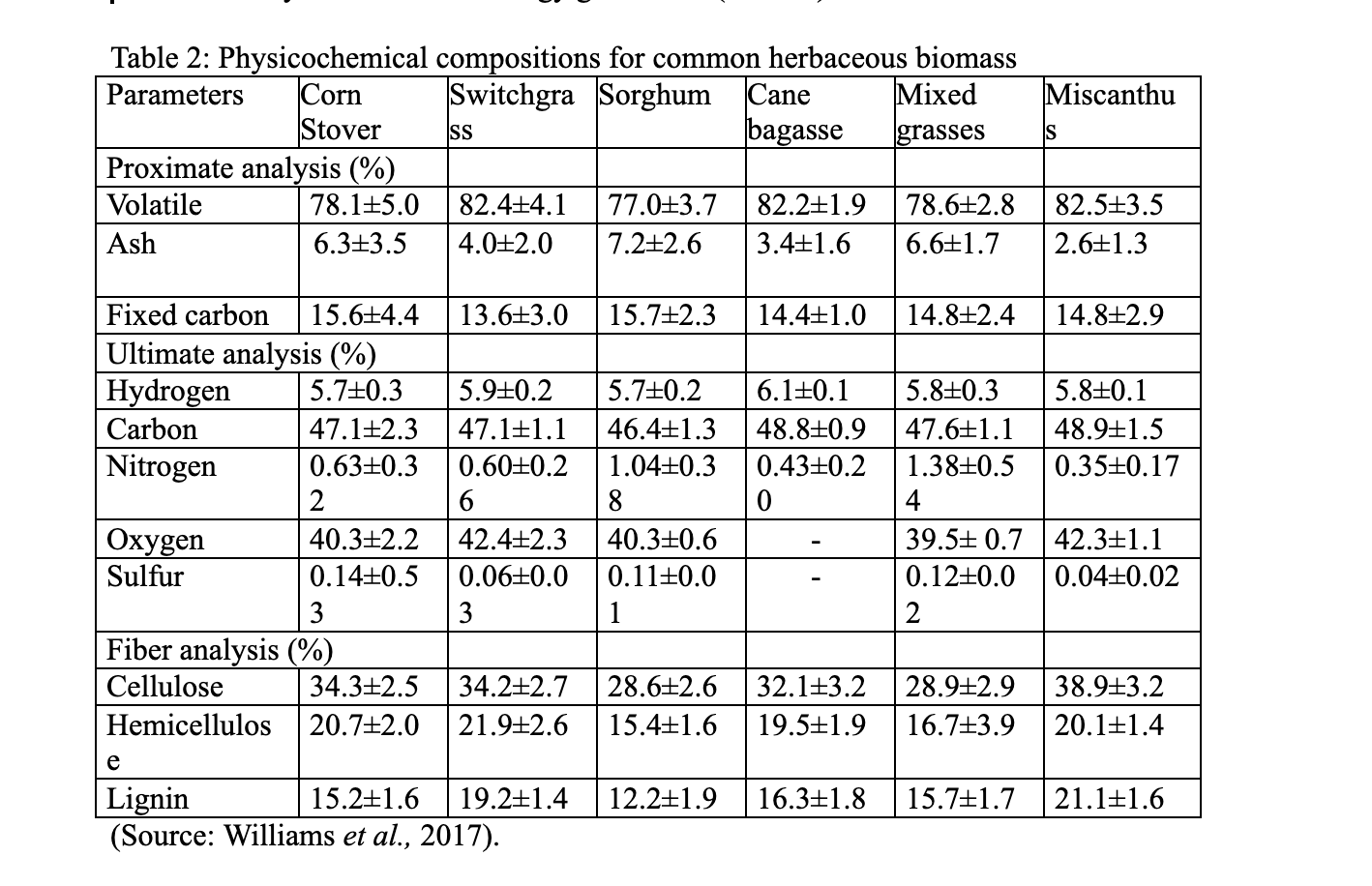

Researchers at the Idaho National Laboratory, Idaho Falls, USA, reported the physicochemical compositional values of common herbaceous biomass wastes such as corn stover, switchgrass, sorghum, cane bagasse, mixed grasses, and miscanthus used in the production of biochar, and renewable energy (Table 2). The report showed that sorghum stover had the lowest fiber fractions followed by mixed grass, while miscanthus, and corn stover had the highest figures. The same trend was observed with the results of the proximate, and some ultimate analysis parameters. These variations are significant enough to warrant different operational conditions, especially pyrolysis temperatures, during the feedstock conversion to biochar. Thus, understanding the degree of biomass compositional variability is crucial to developing robust biochar or activated charcoal production process.

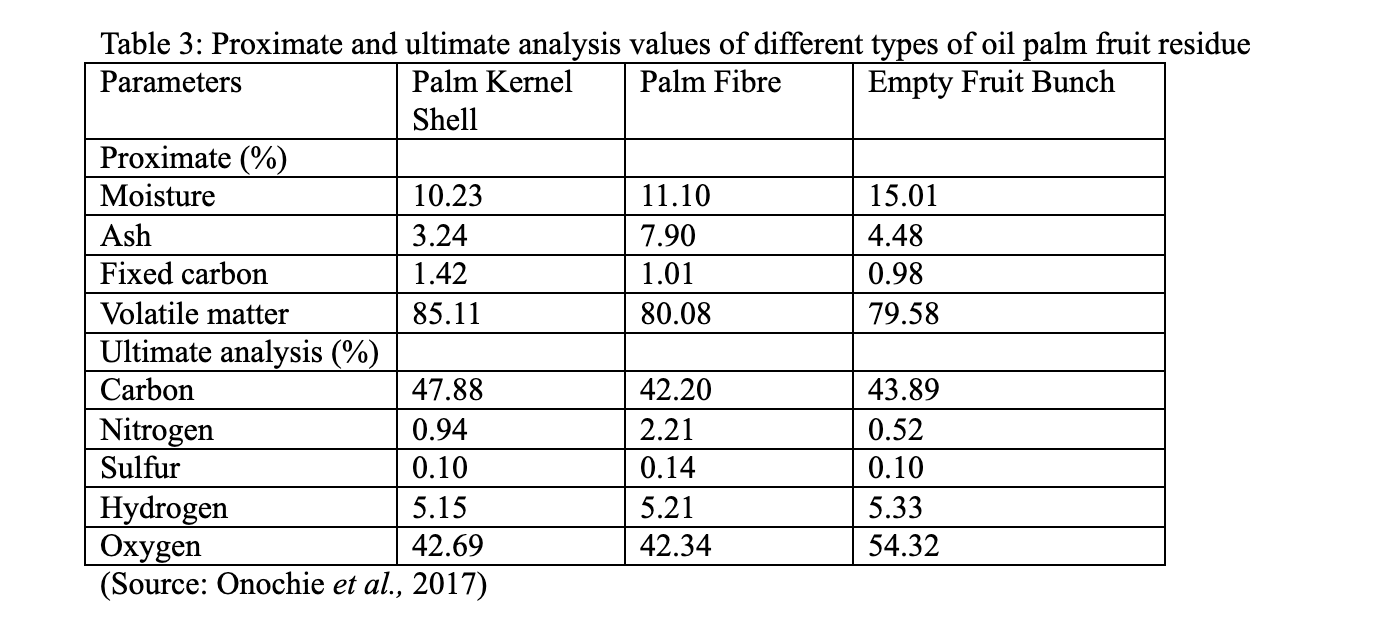

Different types of location-specific biomass residues are produced in abundance in many tropical countries. For example, oil palm residues are major biomass wastes generated from the processing of the oil palm fruit in many tropical countries. The three major solid wastes generated from the processing of the oil palm fruit are the palm kernel shell, palm fibre, and empty fruit bunch. Although these biomass wastes are derived from the same fruit bunch, their physicochemical compositions vary according to their structural characteristics. Researchers at the University of Benin, Benin City, Nigeria, analyzed the proximate, and ultimate values of palm kernel shell, palm fibre, and empty fruit bunch, in order to determine their suitability for renewable energy generation (Table 3).

The palm kernel shell contained more fixed carbon, and volatile matter but less moisture, and ash than the other biomass types, indicating that it is a better feedstock for activated charcoal production. Usually, fixed carbon acts as the main heat generator during burning, and has a significant influence on the calorific value, which implies again that palm kernel shell, and palm fiber will be better suited than the empty fruit bunch for activated charcoal production. These fixed carbon values are however much lower than the values reported in tables 1 and 2, while the ash content of the palm fiber is similar to those of the stovers, and grasses in table 2.

Conclusion

Agricultural, and forestry biomass residues account for 94 percent of the annual global biomass production. Biomass waste has been classified into five categories according to source or origin to include woody biomass, agricultural residues, aquatic plant, human and animal waste, and industrial waste biomass. There are significant physicochemical variabilities between these biomass types, and within individual biomass species. These variabilities arise from the varied growth rates, and harvesting conditions of the biomass residues, and may present challenges during their conversion processes. There is, therefore, the need to determine the physical, and chemical characteristics of biomass wastes before their use in activated charcoal or biochar production.

Bibliographic References

Bhuvaneshwari, S., Hettiarachchi, H., and Meegoda, J.N. (2019). Crop residue burning in India: Policy challenges and potential solutions. International Journal of Environmental Research and Public Health, 16: 832; doi:10.3390/ijerph16050832

Hills, C.D., Tripathi, N., Singh, R.S., Carey, P.J., and Lowry, F. (2020). Valorization of agricultural biomass‑ash with CO2. Scientific Reports, (2020) 10:13801 https://doi.org/10.1038/s41598-020-70504-1

Onochie, U.P., Obanor, A.I., Aliu, S.A., and Ighodaro, O.O. (2017). Proximate and ultimate analysis of fuel pellets from oil palm residues. Nigerian Journal of Technology 36(3): 987 – 990.

Shah, M.S., Khan, M.N.S., and Kumar, V. (2018). Biomass residue characterization for their potential application as biofuels. Journal of Thermal Analysis and Calorimetry, https://doi.org/10.1007/s10973-018-7560-9(01

Sun, X., Shan, R., Li, X., PAN, J., Liu, X., Deng, R. and Song, J. (2017). Characterization of 60 types of Chinese biomass waste and resultant biochars in terms of their candidacy for soil application. GCB Bioenergy, 9: 1423 –1435.

Tripathi, N., Hills, C.D., Singh, R.S., and Atkinson, C.J. (2019). Biomass waste utilization in low-carbon products: harnessing a major potential resource. Climate and Atmospheric Science (2019) 2:35; https://doi.org/10.1038/s41612-019-0093-5

UNEP (2015). Converting waste agricultural biomass into a resource. United Nations Environment Programme Division of Technology, Industry and Economics International Environmental Technology Centre, Osaka/Shiga, Japan.

Williams, C.L., Emerson, R.M., and Tumuluru, J.S. (2017). Biomass compositional analysis for conversion to renewable fuels and chemicals. In: Biomass Volume Estimation and Valorization for Energy. IntechOpen. Pp: 251 – 270. http://dx.doi.org/10.5772/65777