Activated Charcoal 4: Low-Cost Kilns and Production in Small Farms

Published Date: 1st February 2021

Introduction

The production, and uses of activated charcoal/biochar have received increasing global, political, and academic attention due to their association with climate change mitigation, provision of food security, and their recognition as a viable alternative organic waste management approach. Activated charcoal and biochar are therefore finding new applications in the different agricultural sectors, with research, and development efforts increasingly promoting their use in horticulture, animal agriculture, and aquaculture. Low-cost technologies needed for their production are however not readily accessible to small-scale farmers who generate abundant reusable biomass residues in their farms. Simple low-cost technologies that integrate user-friendliness, energy efficiency, ease of adaptation, and limited emissions are needed for the sustainable production of activated charcoal and biochar by these farmers.

In western countries, retorts, defined as airtight vessels in which substances are externally heated to produce gasses that are collected in another vessel for further processing are the standard technology for producing industrial charcoal-based products. Their high investment costs, however, make them unattractive to small-scale activated charcoal production in many developing countries, especially to small-scale farmers. The use of simpler, and easily adoptable technologies such as kilns have been suggested for these farmers. A kiln is a type of oven or thermally insulated chamber that is internally or externally heated to generate sufficient temperature to complete processes such as drying or chemical changes, including carbonization of biomass. When the kiln is designed for the thermal decomposition of biomass, it can be regarded as a pyrolyzer. Such simple low-cost kilns that are filled with biomass feedstock, and run to completion before being emptied, are regarded as batch pyrolyzers.

The drawback to the use of low-cost kilns however includes significant feedstock burns off, lower char yield, and heat energy loss, while their advantages are mainly their simple operation, and design concept. Again, the nature, and type of the pyrolyzer have been shown to have a significant effect on the yield, and the properties of the activated charcoal produced from it, due mainly to the difference in the rates of thermal decomposition. In general, the yield, and biochar characteristics are dependent on the maximum attainable temperatures within the pyrolyzer, such that the higher the energy efficiency, the higher the potential to produce activated charcoal of higher quality. Several design, and socioeconomic factors, however, need to be taken into consideration before promoting a particular type of pyrolyzer in a community. Usually, affordability, fuel flexibility, ease of operation and maintenance, mobility, and safety should be top on the list.

Low-cost kiln designs

Several small-scale approaches to activated charcoal, and biochar production are available. These include the traditional heaps Kon-Tiki kiln, fire pits, many barrel methods, rocket stoves, and gasifiers among others. These however function at high pyrolysis temperatures, and take a longer time to complete the process. Charcoal production with traditional kilns liberates a lot of gasses in form of smoke, and waste heat energy, while the charcoal yield is usually small. Modern kiln designs, therefore, try to control the biomass pyrolysis in order to increase the charcoal yield, and also utilize the energy-rich liquids, and gases generated to drive the pyrolysis reactions. Retort designs are more efficient at excluding oxygen to enable pyrolysis, although they are costlier because of added functions that have to do with energy conservation, and gas emission control. Simpler retort kilns on the other hand are relatively cheap, and have been made from a variety of materials, such as a 15-gallon steel drum placed inside a 55-gallon steel drum. Such retort kilns efficiently exclude oxygen from the pyrolysis process thereby producing quality biochar at scales adoptable by small-scale farmers or producers. These retort kilns are efficient pyrolyzers of small dimension feedstock that do not pack together.

Clay pot pyrolyzer: A simple clay pot pyrolyzer was used by a researcher at the Federal University of Technology Owerri, Nigeria, to successfully carbonize blends of dried pig dung, palm kernel shell, and bamboo sticks. The clay pot of about 3-liter size was loaded with the biomass blend, and set on an open fire as shown in plate 1. Once the fire started, the pot was covered with a lid in form of a clay bowl, and the set-up observed for the appearance of black smoke from the small gap between the pot, and the lid (about 20 minutes). This black smoke was subsequently replaced by white smoke, which signified the completion of biomass carbonization. This pyrolysis method usually lasts about 3 - 4 hours at a temperature range of 300 to 500oC, while physical steam activation is used to activate the char to produce activated charcoal.

Top lit updraft (TLUD): The top-lit up-draft gasifier model is constructed from cylindrical containers, and relies on airflow from two sources. Biomass is placed into a container such as a 55-gallon drum with holes at the base as the primary air source to the system, while a chimney is constructed on the removable cover lid of the drum. A gap is usually created between the cover lid of the drum to serve as a secondary air source for feeding the flame, while the chimney directs the gas out of the system. The TLUD is lit on top so that the biomass burns downwards as shown in figure 1. The design is good for the pyrolysis of small feedstock, and has been shown to produce high-quality char from wood chips, chunks, and bamboo sticks. It may also be effective for co-pyrolysis of small dimension feedstock (sawdust, animal dung, kernels, and shells), and also larger dimension feedstock.

Double barrel retort kiln: This design consists of a 15-gallon steel drum placed inside a 55-gallon steel drum. The small barrel is filled with the biomass material, and then placed inside a bigger barrel as shown in Figures 2 and 3. In some designs, small holes are made on the sides of the small drum to allow for the escape of gasses released during the pyrolysis, while in others the drum with its content is turned upside down. A chimney is also constructed on the lid of the bigger drum to create an up-draft, while holes are drilled at the bottom to serve as a primary air source. The space between the two barrels is loaded with biomass fuel sources which could be wood chips, and dry sticks. To operate the system, the fuel source in between the two drums is ignited at the top, and the system covered with the top lid, and chimney. Just as described for the TLUD, the biomass fuel source burns downwards with the aid of air flowing from the holes at the bottom of the outer barrel, while the up-draft escapes through the chimney. The volatile gases released from the heated biomass in the inner barrel also burns to further aid the pyrolysis process, and limit air pollution, which is a critical factor in many countries.

Characteristics of activated charcoal produced from selected biomass wastes

The pyrolysis, and gasification behavior of lignocellulosic biomass depends on their compositions of cellulose, hemicelluloses, and lignin. The proportions of these constituents influence the proportion of carbon stabilized in biochar. Therefore, varying char yield, and characteristics are usually obtained from different biomass species depending on their differences in physicochemical composition. Higher lignin content, for example, has been associated with the lower pyrolysis weight loss, and therefore higher char yield at carbonization temperatures of about 500˚C. Again, biochar or activated charcoal prepared from different biomass materials, and with different methods have been shown on analysis to record different total carbon, pH, liming effect, electrical conductivity, cation exchange capacity, density, and specific surface area values. The farmer is therefore expected to be conversant with the varied chemical characteristics of char produced from locally available biomass before using them in horticulture, livestock, or aquaculture farming. Basically, the price, purity, ease of activation, and potential expectations will be the main considerations in choosing the starting raw materials whether it is of animal, mineral, or plant origin. The major considerations guiding research on the use of agricultural wastes as precursors for the production of activated charcoal in recent years, however, have been based on renewability, cheapness, availability, and environmental friendliness.

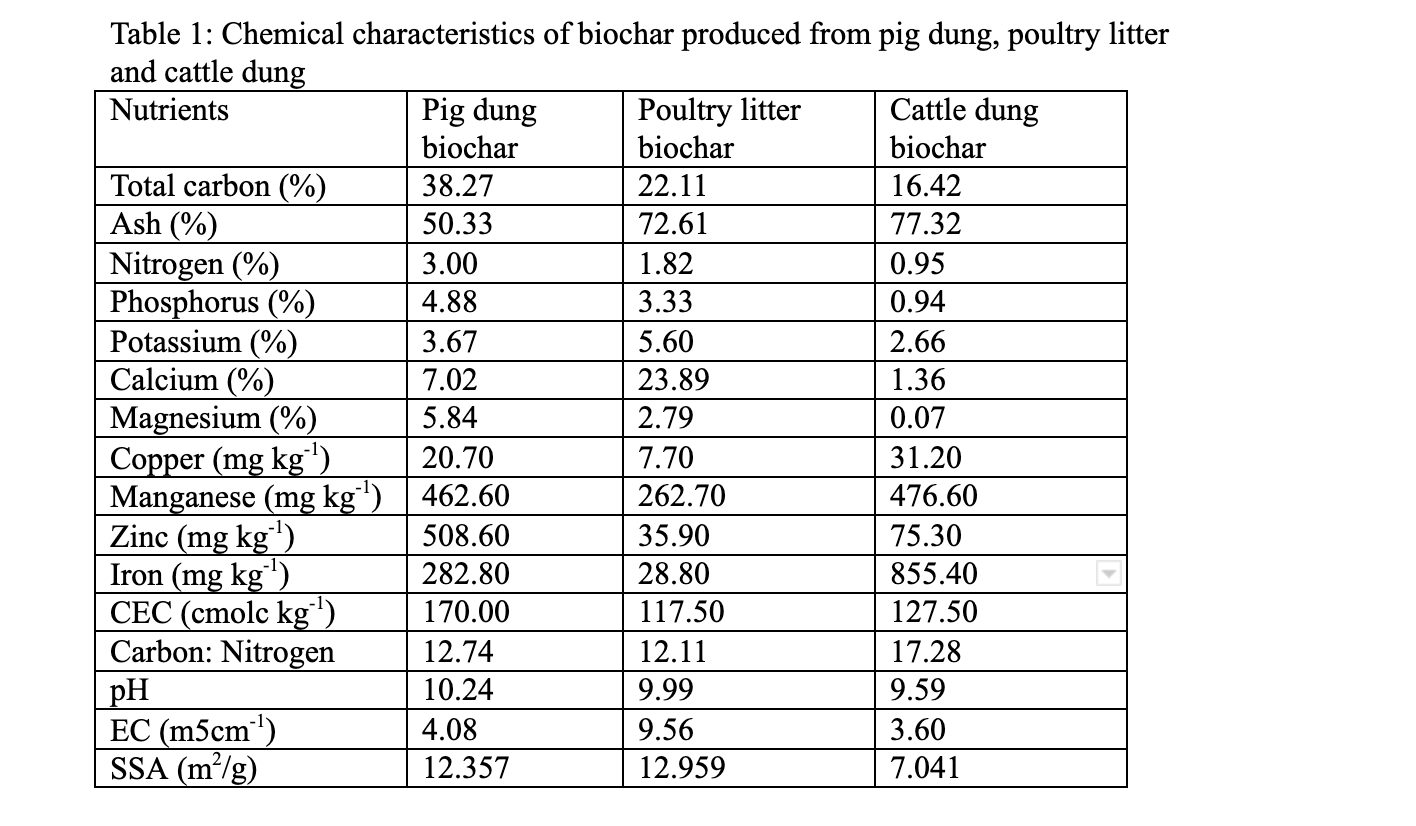

Animal dung: Researchers at the Federal University of Santa Maria, Brazil, studies the chemical characteristics of biochar produced from pig dung, poultry litter, and cattle dung after carbonization at 450°C for one hour. They reported 58 and 57 percent carbon yield from cattle dung, and poultry litter respectively, which were much higher than that of pig dung. The values in table 1 showed that total carbon was highest in pig dung, and lowest in cattle dung, although results obtained elsewhere through slow pyrolysis at 300oC for 4 hours showed lower carbon in pig (18.88 percent) than in cow dung (27.31 percent). Several studies have reported that the biochars produced from animal dung have relatively lower total carbon when compared with the values obtained from plant materials. This has been attributed to the presence of more labile organic compounds in animal dung which are usually lost rapidly at high temperatures before the formation of recalcitrant compounds.

Again, nitrogen, phosphorous, magnesium, and zinc contents of pig dung were much higher than obtained in the other manure samples. Poultry litter had comparatively high calcium, and potassium contents, while the cattle dung was exceptionally high in iron. The NPK values, therefore, show that the pig dung, and poultry litter derived biochars are superior to that of the cattle dung. The ash content of the animal dung derived biochars were generally high at the range of 50.33 percent in pig dung biochar and 77.32 percent in cattle dung biochar. This is indicative of the high concentration of mineral constituents in the animal manures used in producing the biochars.

Cation exchange capacity, which is a measure of the ability of the biochar to absorb cations was highest in pig dung, while poultry litter, and cattle dung values were relatively similar, and much lower. The carbon: nitrogen ratios were highest in the cattle dung-derived biochar, indicating that it will have a better effect on the nitrogen cycle in the soil than the biochars produced from pig dung, and poultry litter, which recorded similar but lower values. Again, the biochars were generally alkaline, while their electrical conductivity, which is their concentrations of all soluble salts was much higher in the biochar derived from poultry litter. The specific surface area of the biochars produced from pig dung and poultry litter were also similar, and much higher than the value recorded for cattle dung biochar.

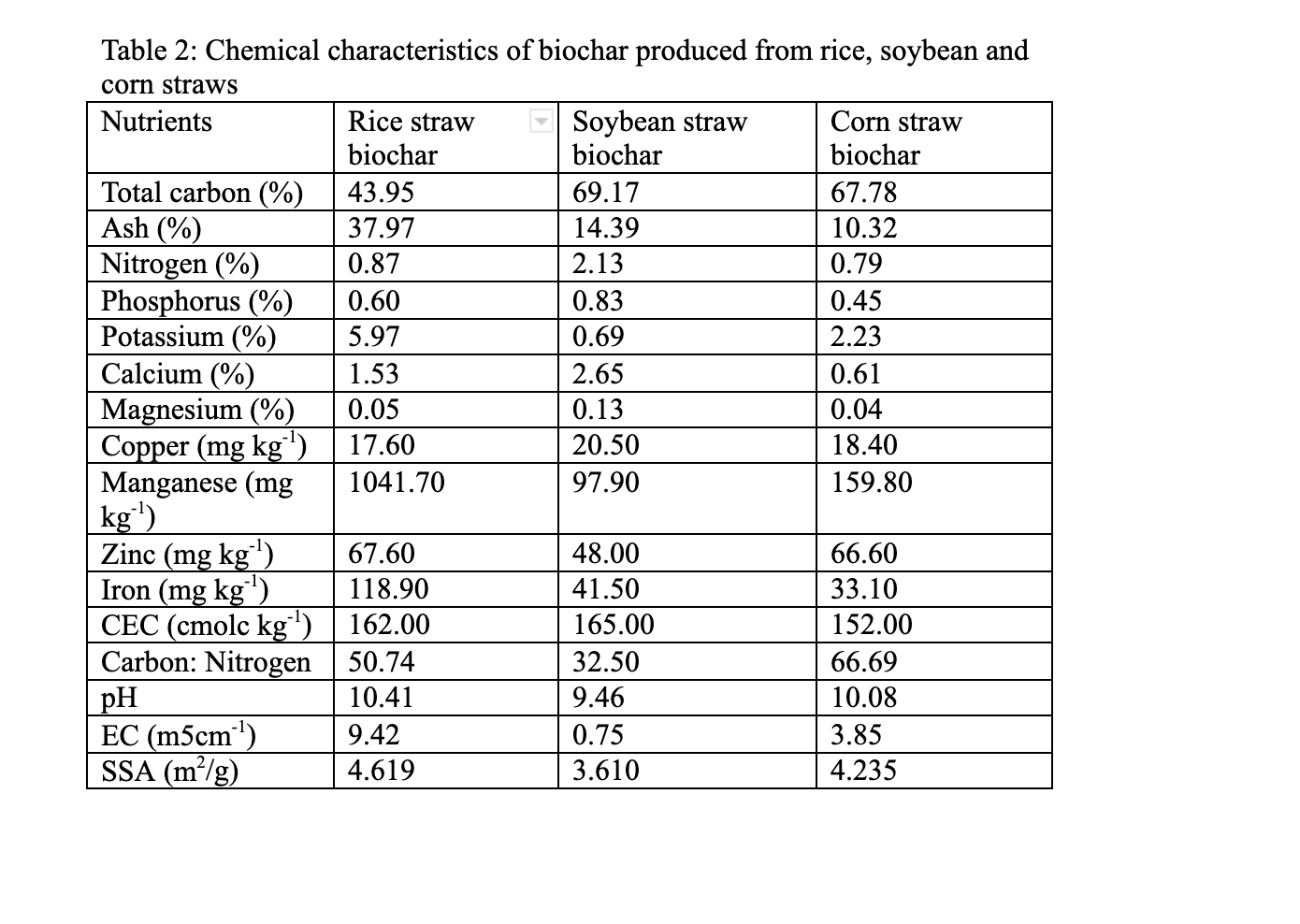

Crop straws: The researchers at the Federal University of Santa Maria, Brazil, also studied the chemical characteristics of biochar produced from common crop residues such as rice straw, soybean straw, and corn straw, and compared the results with the values obtained for the different animal manure derived biochars. The values presented in Table 2 showed that the straw derived biochars had much higher total carbon, ranging from the 43.95 percent recorded in rice straw to the 69.17 percent recorded in soybean biochar, than the values recorded in animal manure (16.42 – 38.27 percent). The straw-derived biochars on the other hand recorded much lower ash content (10.32 – 37.97 percent) than the animal manure biochars (50.33 – 77.32 percent). The animal manure derived biochars generally recorded much higher phosphorus, calcium, magnesium, manganese, zinc, iron, and specific surface area values than the straw derived biochars. These higher mineral values probably reflect the higher ash content reported in the animal manure derived biochars. Rice straw-derived biochar however recorded an exceptionally higher manganese value (1041.70 mg kg-1) than all the biochars analyzed. The straw derived biochars generally recorded higher cation exchange capacity, and carbon: nitrogen ratios, while potassium and pH values were within similar ranges.

These results invariably highlight the fact that the biochars produced from crop straws are richer in carbon contents than those produced from animal manures, have better CEC and pH, values and therefore will be more beneficial in terms of improving soil nutrients retention capacity, and pH, when applied in acidic soils. Other studies have however reported that manure-derived biochar inherently contains higher ash content, higher water-soluble salts, and higher cationic exchange capacity than plant-derived biochar, which makes the manure-derived biochar a more effective adsorbent for soil remediation.

Oil palm wastes: Oil palm biomass residues such as the old trunk, frond, empty fruit bunch press fiber, and kernel shell are produced in abundance in most oil palm producing countries of the tropics where they have been processed into different value-added products or discarded as waste, with varying environmental consequences. The pyrolysis of oil palm biomass allows for better energy recovery and production of fewer pollutants than other options, since a varied range of products of solid, liquid, and gaseous nature that have numerous applications are produced. Thus, oil palm wastes are increasingly transformed into different bio-oil, gas, and biochar or activated charcoal through pyrolysis. These biomass residues are specifically known to contain high concentrations of carbon, and are therefore good feedstock for biochar production. For example, it has been reported that pyrolysis of palm kernel shells at 7500C for 1-hour yields quality biochar for carbon fuel utilization.

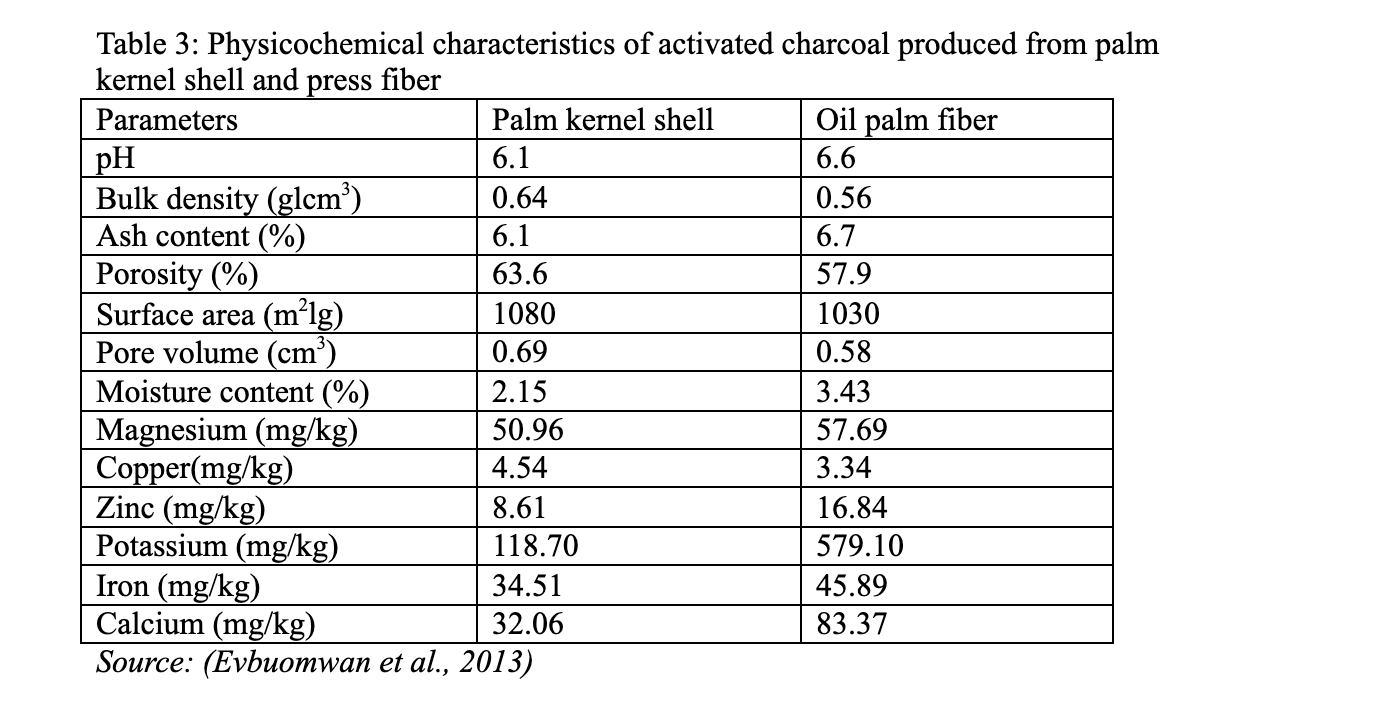

Researchers at the University of Port Harcourt, Rivers State, Nigeria, studied the physicochemical properties of activated charcoal produced from kernel shell, and press fiber, and reported the values shown in table 3. The study showed that the activated charcoal prepared from palm kernel shell has superior physicochemical properties for adsorption than that prepared from the pressed fiber. The activated charcoal prepared from the pressed fiber however contains a much higher level of potassium, therefore, making it more suitable for the production of organic fertilizer.

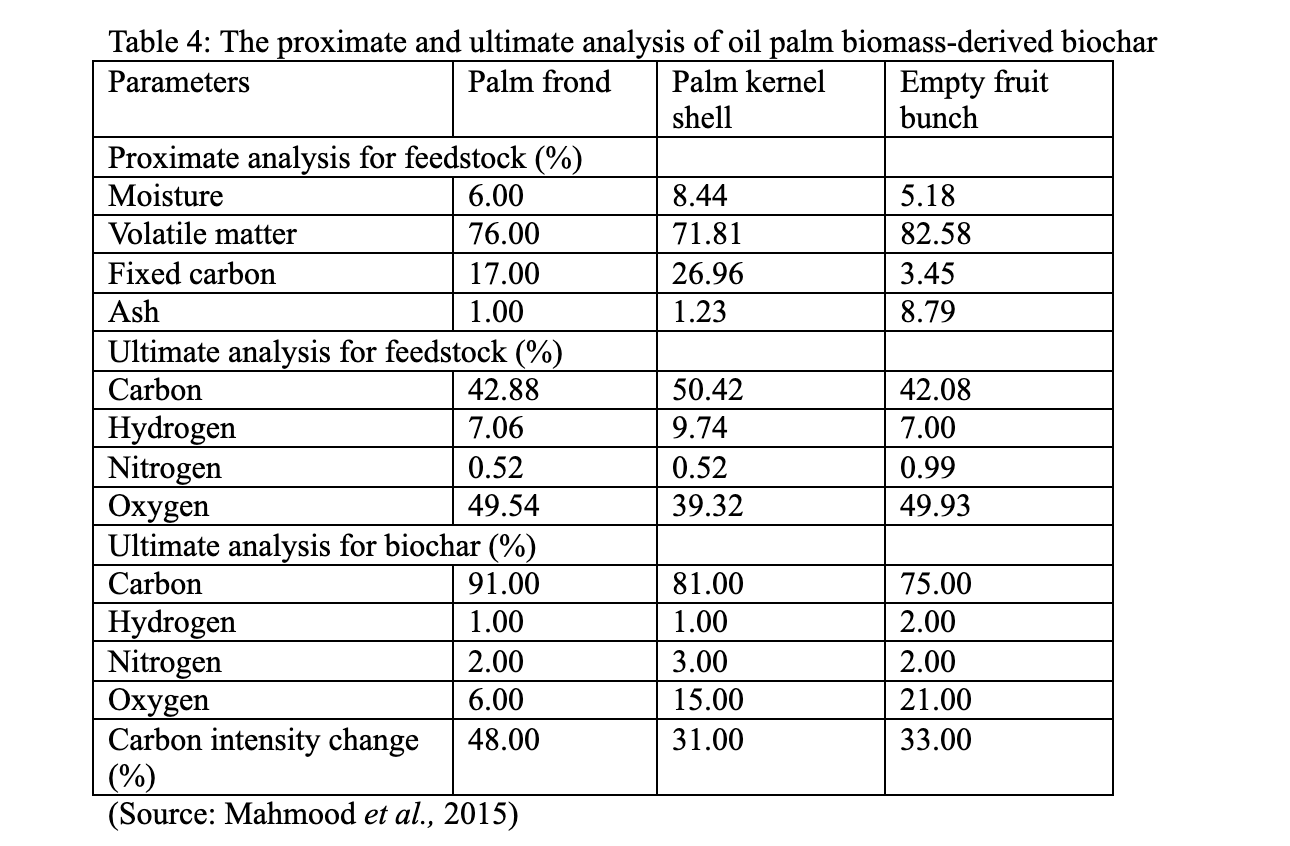

A study carried out at the University KM Bangi, Selangor DE, Malaysia, also investigated the characteristics of biochar produced during gasification oil palm wastes such as oil palm frond, palm kernel shell, and empty fruit bunch. The biochars were produced with a medium-scale downdraft gasification process with an operating reactor temperature of 650 - 800ºC. The biochars recorded carbon content, and calorific value ranges of 75 – 91 percent, and 26 - 29 MJ/kg, respectively, as shown in table 4. The biochar derived from the oil palm frond recorded the highest surface area (891 m2/g), and adsorption capacity (250 cm3/g). The carbon content values were very much higher than those recorded in biochars produced from crop straws, and animal manure. Such high carbon content in biochar is important for carbon sequestration during soil application.

Sawdust, and wood wastes: Biomass residues from wood processing mills such as wood sap, sawdust, and wood shaven are also abundantly available in many tropical countries. While the wood saps, and chips are used as fuel in open fire for cooking, the shaven is used as litter material in commercial livestock production. Sawdust is however sparingly used in cooking, while most of it is discarded as waste in Nigeria, and other African countries as abundant waste material, which are usually openly burnt to reduce their volume, thus constituting a serious environmental hazard. The preparation of activated carbon from wood-based industrial residue like sawdust from sawmills is, therefore, an environmentally friendly solution capable of transforming the waste into valuable material.

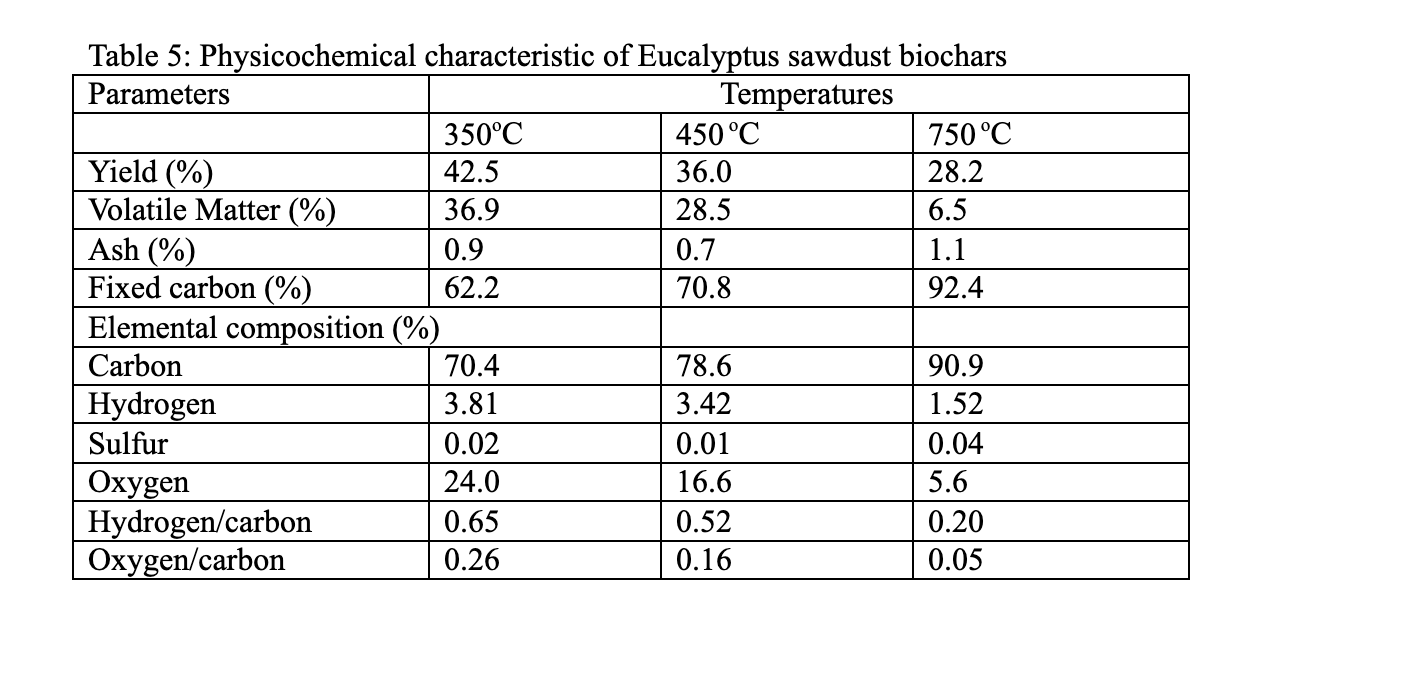

Researchers at the Universidade Federal de Lavras, Minas Gerais, Brazil, investigated the Properties of biochar derived from Eucalyptus sawdust and reported the values shown in table 5.

The wood wastes were carbonized at 350, 450, and 750oC and subsequently characterized to identify their agronomic, and environmental benefits. The carbon yield decreased with increasing carbonization temperature, while the fixed carbon content increased in line with earlier reports. Biochars manufactured from Eucalyptus sawdust, regardless of the pyrolysis temperature employed, have the potential for increasing carbon storage in soils, as the biochar characteristics increase along with pyrolysis temperature (Table 5). The high carbon concentration, low H/C ratio, were particularly of importance in improving C storage in tropical soils.

Conclusion

Several low-cost, and easy to make small-scale biochar, and activated charcoal retort kiln designs are readily accessible to rural farmers in the tropics. The double-barrel design consisting of a 15-gallon steel drum placed inside a 55-gallon steel drum however seems to be the most popular design because of its ability to conserve some heat, and reduce air pollution. Other advanced adaptations of this design consisting of more than one drum in the outer container have also been produced to increase the processing volume of such retort kilns. However, affordability, fuel flexibility, ease of operation and maintenance, mobility, and safety remain the major considerations in choosing the type of retort kilns to use.

Since there is wide geographical diversity of biomass residues according to the type of crops, and trees are grown in different parts of the world, the choice of biomass waste will depend chiefly on availability, and ease of gathering. However, varying char yield, and characteristics are usually obtained from different biomass species depending on their differences in physicochemical composition. The oil palm, wood, and sawdust residues have been shown to produce biochars, and activated charcoals of higher quality than the crop straws in terms of char yield, carbon content, porosity, and other characteristics.

Bibliographic references

Domingues, R.R., Trugilho, P.F., Silva, C.A., Melo, I.C.N. Ad., Melo, L.C.A., Magriotis, Z.M. and SaÂnchez-Monedero, M.A. (2017). Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE, 12(5): e0176884. https://doi.org/10.1371/journal.pone.0176884

Edo, F.A. (2019). Studies on the environmental concerns of pig production and strategies for developing value-added products from pig dung. Ph.D. Seminar Paper, Federal University of Technology, Owerri, Nigeria.

Evbuomwan, B.O., Abutu, A.S. and Ezeh, C.P. (2013). The effects of carbonization temperature on some physicochemical properties of bamboo-based activated carbon by potassium hydroxide (KOH) activation. Greener Journal of Physical Science, 3(5): 187-191.

Jessica Dennis. Biochar manual for small farms in BC. Faculty of Land and Food Systems, University of British Columbia, Canada. https://sites.google.com/site/fcfcbiocharmanual.

Mahmood, W.M.F.W., Ariffin, M.A., Harun, Z., Md. Ishak, N.A.I., Ghani, J.A., and Ab. Rahman, M.N. (2015). Characterization and potential use of biochar from gasified oil palm wastes. Journal of Engineering Science and Technology, Special Issue on 4th International Technical Conference 2014, Pp: 45 - 54

Nsamba, H.K., Hale, S.E., Cornelissen, G. and Bachmann, R.T. (2015). Sustainable technologies for small-scale Biochar Production—A Review. Journal of Sustainable Bioenergy Systems, 5: 10 - 31.

Peterson, S.C. and Jackson, M. (2014). Simplifying pyrolysis: Using gasification to produce corn stover and wheat straw biochar for sorptive and horticultural media. Industrial Crops and Products, 53: 228 - 235.

Sarfaraz, Q., Silva, L., Drescher, G., Zafar, M., Severo, F., Kokkonen, A., Molin, G., Shafi, M., Shafique, Q., and Solaiman, Z. (2020). Characterization and carbon mineralization of biochars produced from different animal manures and plant residues. Scientific Reports, 10:955 https://doi.org/10.1038/s41598-020-57987-8