Oil Palm Tree Wastes 11: Other by-products from the processing of oil palm fruit

Published Date: 14th December 2020

Introduction

Added to the plantation wastes comprising palm fronds and trunks, and the oil milling wastes namely the empty fruit bunches, oil palm shell, mesocarp fibres, palm oil mill effluent, and palm kernel meal that constitute the major wastes, and by-products of oil palm processing, other minor by-products are also generated, especially from the refining of the crude palm oil. These minor by-products include palm oil mill sludge (POMS), oil palm decanter cake (OPDC), fatty acid distillate (PFAD), spent bleaching earth (SBE), palm oil fuel ashes (POFA), and palm oil clinkers (POC). During the processing of the palm kernel nuts into kernel oil, and meal, another minor by-product, the palm kernel oil sludge (PKOS), is also produced. Studies have been carried out on the possible reuse of these by-products in the palm oil mill or their conversion into value-added products that will generate extra monetary returns to the industry. This approach is in line with both the international and national policy objective of zero-biomass waste discharge that advocates the reuse, and conversion of available biomass into renewal by-products. Indeed, any strategy that minimizes waste generation by converting it into valuable by-products is usually supported by the industry and governments.

Palm oil mill sludge (POMS) has been estimated to represent about 18 percent of the palm fruit bunch. The POMS is usually discharged onto sand beds, and dried before use as fertilizer. This disposal approach however creates problems such as the breeding and multiplication of insects, and bad odor, therefore vermicomposting of the POMS as an alternative approach has been researched. As a fertilizer, POMS enhances the cation exchange capacity, organic carbon, and nutrients in soils, and reduces the leaching of nutrients underground, and the high cost of fertilizer usage. It is also a potential alternative feedstock for biodiesel production. The oil palm decanter cake (OPDC) is one of the several wastes produced during the processing of oil palm, and accounts for about 3.5 percent of the fresh fruit bunch. Research has shown that the high nutrient composition of the decanter cake makes it a potential source of nutrients for plant growth, and animal nutrition. Its biodegradable organic contents also make it an attractive feedstock for biogas, and compost production. The edible crude palm oil can also be refined in order to remove undesirable components such as free fatty acids, partial acylglycerides, metals, colored compounds, and odorous substances. This Refining process which involves degumming, neutralization, bleaching, and deodorization of the crude palm oil results in the production of a deodorizer distillate, which contains mostly FFAs, and minor concentrations of tocopherols, squalene, and phytosterols, and known in the industry as the palm fatty acid distillate (PFAD). Global annual production estimates for 2015 was 2.98 million tons of PFAD, valued approximately at about $1.493 billion.

The crude palm oil refining process which involves degumming, and bleaching also generates large quantities of spent bleaching earth (SBE), which constitutes another solid waste produced by the palm oil industry. It has been estimated that more than 600,000 metric tons of bleaching earth were utilized in refining the millions of tons of palm oil being produced worldwide. Although SBE contains about 20 – 40 residual oil, it has traditionally been disposed of by incineration, and landfilling method, with the risk of fire, and pollution hazards. This is chiefly a result of the degradation of the residual oil in the SBE, and the associated greenhouse gas (GHG) emissions. In recent times, however, SBE has increasingly been beneficially applied to animal feeding, concrete manufacturing, residual oil recovery for biodiesel production, and use as an adsorbent. Other wastes such as the palm oil fuel ash (POFA), and palm oil clinkers (POC) are residue wastes derived from the burning of palm oil husk or fibre, and palm kernel shell as fuel for the boilers. This burning process is the phase that generates the energy needed to heat the boilers in palm oil mills, and usually represents about 20 percent by weight in the form of ash (5 percent) and clinker (15 percent) produced after the burning process. Research has proven that these materials, especially the ash could be used as construction material, fertilizer, and a detergent.

The oil palm decanter cake (OPDC)

During the industrial extraction of oil from the fresh fruit bunch, a mixture of the various proportions of palm oil (35 – 45 percent), water (45 – 55 percent), and fibrous materials are produced as the crude palm oil from the screw press. The crude oil is refined by pumping it through a horizontal or vertical clarification tank to skim the oil from the top of the clarification tank before passing it through a high-speed centrifuge, and a vacuum dryer, and finally to the storage tanks. The major wastes produced from this refining process are wastewater, and the decanter cake. The oil palm decanter cake (OPDC) is therefore a brown-blackish paste produced during the extraction phase of processing for palm oil, and is characterized by high moisture content (78.20 percent), high degradability, high organic content, and nutrient-rich constituents. Specifically, it contains about 12.63 percent crude protein, 7.12 percent ether extract, 25.79 percent crude fibre, 0.03 percent calcium, and 0.003 percent phosphorus. Other studies reported further that OPDC contains 2.42 percent nitrogen, 0.51 percent phosphorus, 1.24 percent potassium, 0.54 percent magnesium, and 1.68 percent calcium, while 43.73 percent carbon, 2.93 percent nitrogen, 5.9 percent hydrogen, 0.39 percent sulfur, and 31.7 percent oxygen has also been reported as its ultimate analysis. The fatty acids components are usually palmitic, oleic, linoleic, stearic, and myristic acids. OPDC has also recorded a biological oxygen demand of 46.54 g/kg, a chemical oxygen demand of 138.92 g/kg, and an oil content of 13.60 percent.

OPDC has been used in combination with inorganic fertilizer to improve soil quality in palm plantations. It has also been utilized in the production of enzymes such as cellulase as well as polyose, and natural polymer composites. Several studies have shown that OPDC could be fed to goats without deleterious effects. Specifically, researchers at the University Putra Malaysia, Malaysia, studied the potential value of OPDC as a cheap alternative feedstuff to reduce the cost of feeding goats under intensive production systems. The goats were assigned to one of four concentrate diets (16 percent crude protein on a dry matter basis) containing OPDC (12.8 percent crude protein) at the rate of 0, 10, 20, and 30 percent for 105 days. The study showed that in terms of growth performance, carcass characteristics, and cost of feeding, the palm oil decanter cake could be included in the diets of goats up to 30 percent with superior results. Feeding OPDC has also been reported to increase the populations of cellulolytic bacteria, while decreasing the population density of methanogenic archaea in the rumen of goats, resulting in better growth performance.

Palm fatty acid distillate (PFAD)

Palm fatty acid distillate is a highly viscous, cheap (about 85 percent less than the cost of palm oil), and valuable by-product of edible oil processing industries containing 96.1 percent FFAs, glycerides, and other minor valuable components such as squalene (0.76 percent), hydrocarbons (0.71 percent), phytosterols (0.37 percent) tocopherols, and tocotrienols (0.48 percent) as well as mono and di-glycerides. It accounts for about 4 – 5 percent of the crude palm oil. A study of the chemical characteristics of PFAD at the University of Sindh, Jamshoro, Pakistan, reported that it contains 0.06 - 7.50 percent moisture, and 65.70 - 94.68 percent FFA made up of 0.04, 0.42, 41.25, 7.29, 41.58, 8.95, 0.04, 0.27, 0.07, and 0.05 percent lauric, myristic, palmitic, stearic, oleic, linoleic, eicosenoic, docosanoic, arachidic, and tetracosanoic acid respectively.

Due to its high concentration of FFAs, PFAD has been used in the production of biodiesel, polyols, animal feeds, candles, and soaps, while its content of tocopherols, and phytosterols, lends to several applications in foods, and cosmetics industries. PFAD can be refined to produce a tocotrienol-rich fraction, which has both antioxidant, and cholesterol-lowering properties, and has therefore been used to improve the lipid profile, and hepato-protector, immunomodulatory, antioxidant, and lactogenic responses in the experimental animal. The high viscosity of PFAD is a major drawback to its use in biodiesel production. This has however been overcome by blending it with diesel fuel at optimal volumetric ratios of 2 – 10 percent in order to bring its density, viscosity, surface tension, and flash point to values similar to those of diesel fuel.

Spent bleaching earth (SBE)

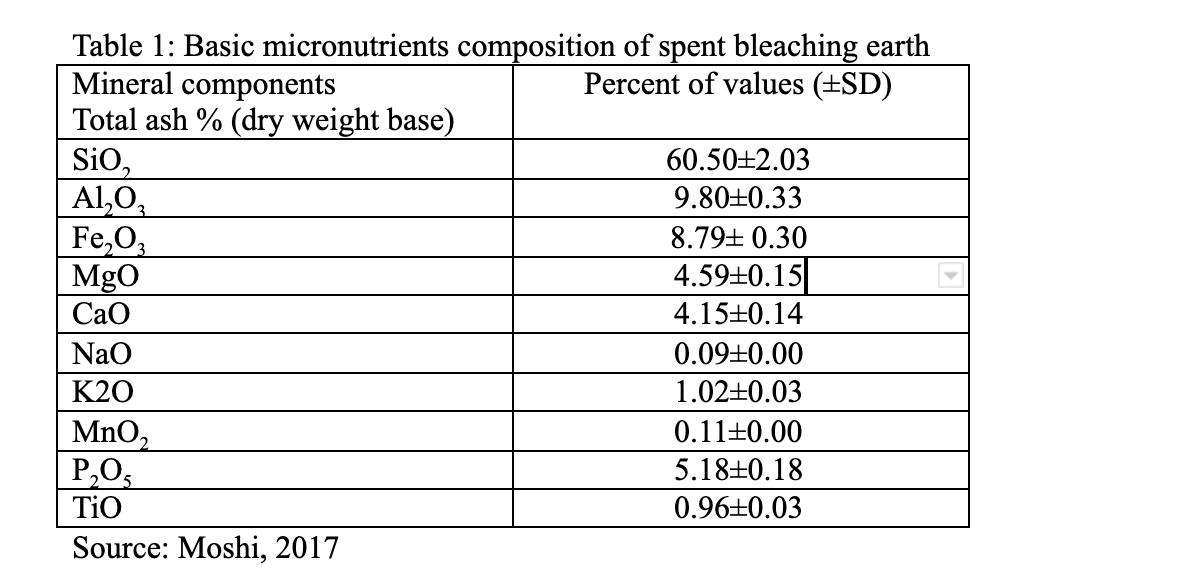

The spent bleaching earth generated during the palm oil refining process has an unpleasant odor, and contains clay minerals, and residual oil. On a dry weight basis, SBE contains 1.94 percent moisture, 98.06 percent total solids, 34.61 percent volatile solids, 65.39 percent ash, 20.56 percent organic carbon, 28.52 percent total carbon, 0.08 percent total nitrogen, 256.5 carbon: nitrogen ratio, 2.25 phosphorus, and 0.65 percent potassium. The mineral components are shown in table 1. It was traditionally discarded in landfills where the residual oil undergoes rapid oxidization due to the autocatalytic actions of the clay minerals resulting sometimes in spontaneous auto-ignition. Direct discharging of spent bleaching earth into landfills, therefore, has serious environmental pollution consequences, and has been discouraged by regulatory agencies.

These environmental issues, and the high costs associated with the large area of land needed for storage of SBE has led to research interests in its reuse or recycling. For example, several extraction processes have been used to recover the residual vegetable oil from the SBE. Processes such as soxhlet extraction using hexane as the solvent, semipermeable membrane separation technology, subcritical water technology that uses water instead of organic solvents, and supercritical fluid extraction that utilizes non-hazardous carbon dioxide as a solvent have been employed successfully in the extraction of residual oil from the SBE. However, the soxhlet extraction method not only requires high operating cost but also causes additional environmental problems, and is therefore being replaced by more advanced extraction methods such as the supercritical fluid extractions, and membrane technologies which are faster, and also achieve higher quality yield.

Innovative approaches such as low-pressure compaction followed by heat treatment at 150ºC to cause the polymerization of the residual organic components in the SBE have been used to produces monolithic clay blocks with high compressive strengths for use in the construction industry. Research studies on the use of spent clay co-composted with rice husk, rice husk ashes, chicken litter, and other readily available biomass or agriculture by-products as a soil amendment to improve soil fertility, and plant growth have also been tried. For example, Researchers at the Malaysian Palm Oil Board, Kuala Lumpur, Malaysia, demonstrated an innovative co-composting of SBE with some agricultural, and palm oil milling by-products to produce bioorganic fertilizer, and tested the effects on soil physical attributes, and microbial rejuvenation for the productivity of okra, kangkung and groundnut magenta. The composted SBE had a positive impact on soil physical attributes due to adequate amounts of beneficial mineral elements; improved organic carbon, cation exchange capacity, water-holding capacity, and C: N ratio, with 2-fold increases (35 – 60 percent) in the fresh and dry matters production of the crops. A study at the Tanzania Industrial Research, and Development Organization, Dar es Salaam, Tanzania, evaluated the effect of SBE on cow manure-based biogas production. The SBE was mixed with manure at the rate of 10, 20, 30, 40, 50, and 100 percent for the biogas production. A methane yield of 85 percent was achieved with the SBE, compared to the theoretical yield of methane from lipids. The 50 percent co-digestion of cow manure, and SBE improved methane yield by 9-fold, while the yield from the 100 percent SBE was 16-fold that of 100 percent cow manure, indicating that SBE is a cheap, excellent substrate for biogas production.

Palm oil fuel ashes (POFA)

POFA is the major solid wastes in the form of ash produced from the combustion of palm oil residue wastes such as fibers, shells, and empty fruit bunches in power plants to generate electricity. After combustion, approximately 5 percent by weight of the residue waste remains as POFA, with silicon dioxide (SiO2) being the major chemical constituent. It is basically a non-crystalline silicon dioxide, mostly in amorphous form having a high specific area, and pozzolanic activity. Traditionally, POFA has been disposed of in landfills because it had very limited industrial value. This practice has however elicited environmental concerns. In recent times, POFA has been used as a pozzolanic material in concrete because of its mechanical properties such as compressive strength, and modulus of elasticity that it confers on concretes. Specifically, POFA has been used to replace cement as a binder in geopolymer mortar, and concrete to improve the compressive strength, and durability in terms of chloride ion penetration, and corrosion resistance of high strength, and high workability. Partial addition of POFA to cement is of advantage, especially for mass and asphaltic concrete works.

Researchers at the King Mongkut’s University of Technology Thonburi, Bangkok, Thailand, studied the effects of different ratios of POFA on compressive strength, water permeability, and chloride resistance of concrete at partially replace rates of 15, 25, and 35 percent by weight of the binder. The results showed that POFA concrete with a W/B ratio of 0.40 had compressive strengths ranging from 45.8 to 55.9 MPa or 82 – 94 percent of OPC concrete at 90 days, while POFA concrete with a W/B ratio of 0.50 had the compressive strengths of 33.9–41.9 MPa or 81–94 percent of OPC concrete. The findings also showed that water permeability, and chloride ion penetration of POFA concrete were significantly reduced compared to OPC concrete.

Palm oil clinkers (POC)

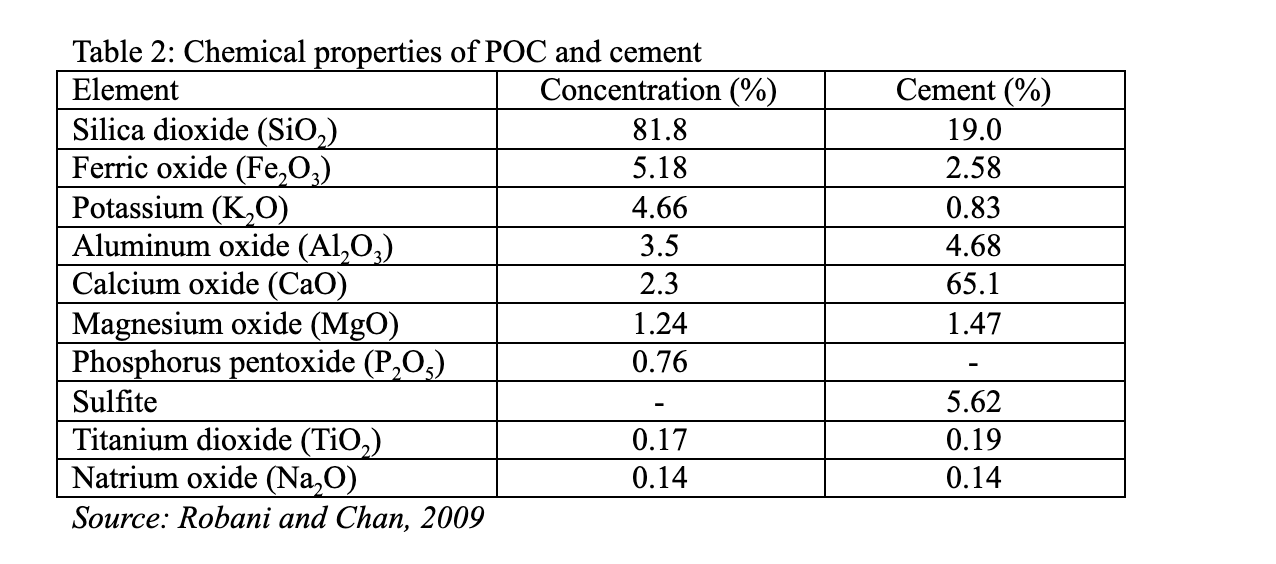

POC is another by-product from the combustion of palm oil biomass residue wastes in the mill boiler. When mesocarp fibre, and oil palm shell are combusted, about 5 percent of POFA, and 15 percent of POC are produced, indicating that more POC than POFA is produced. It has the appearance of a gray-colored porous stone, which is usually flaky, and irregular with rough, and spiky broken edges. Physically it has an aggregate size of <5 –14, specific gravity (2.15 - 1.73), water absorption (3 – 10 percent), moisture content (0.5 – 1 percent), and bulk density (732 -811 kg/m3). It has lower bulk density but high water absorption capacity than sand. The chemical properties are compared with that of cement in table 2.

Traditionally, POC was disposed of in landfills or incinerated at an extra cost. Thus, large volumes may accumulate at the disposal sites, thereby causing environmental, and pollution problems. POC can however be utilized as a replacement for sand in the production of durable structural lightweight concrete to create cheaper, and renewable aggregates for buildings, and road construction. Studies at the University of Malaya, Kuala Lumpur, Malaysia, specifically determined that the replacement of fine aggregate with POC has no significant effect on compressive strength. However, fresh concrete workability was found to decrease with an increase in the replacement ratio of coarse aggregate with POC, except for the river sand replacement. Again, the compressive strength of concrete containing coarse POC aggregate was found to be inversely proportional to the replacement level, implying that the compressive strength of the concrete decreases with an increasing level of coarse POC in the mix.

Palm kernel oil sludge (PKOS)

The palm kernel oil sludge is a dark brown/black colored residue left as dredge during the refining of palm kernel oil. It has been used both as animal feed raw material, and as fertilizer for crop production. Researchers at the Rivers State University, Port Harcourt, Nigeria, fed laying birds, and broiler chickens diets containing 30 g dry matter of palm kernel oil sludge, and reported the apparent metabolizable energy, and the true metabolizable energy for the laying hens to be 3.14 and 2.98 Kcal/kg DM, while the values for the broiler chickens were 3.12 and 2.96 Kcal/kg DM respectively.

Conclusion

Added to the major biomass residue wastes produced from the production, and processing of palm oil, other minor by-products include palm oil mill sludge, oil palm decanter cake, fatty acid distillate, spent bleaching earth, palm oil fuel ashes, and palm oil clinkers are also produced. Research has shown that these by-products could be reused or converted into valuable by-products in order to minimize waste generation in line with current environmental policies.

Bibliographic references

Abutaha, F., Razak, H.B., and Kanadasan, J. (2016). Effect of palm oil clinker (POC) aggregates on fresh and hardened properties of concrete. Construction and Building Materials, 112: 416 – 423.

Asha, E. (2016). Effects of oil palm decanter cake on growth of selected vegetables. Ph.D. Thesis, Universiti Sains, Malaysia.

Chang, A.S., Sherazi, S.T.H., Kandhro, A.A., Mahesar, S.A., Chang, F., Shah, S.N., Laghari. Z.H. and Panhwar, T. (2016). Characterization of palm fatty acid distillate of different oil processing industries of Pakistan. Journal of Oleo Science, 65(11): 897 - 901.

Gafar, A.A. Alimon, A.R., Sazili, A.Q., Man, Y.C., and Abubakr, A.R. (2013). Effect of Varying Levels of Palm Oil Decanter Cake on Feed Intake, Growth Performance, and Carcass Characteristics of Kacang Goats. Journal of Agriculture and Veterinary Science, 3(4): 24 – 29.

Liew, W.L., Azraai, K.M.M., Affam, A.C., and Kheang, S. (2017). Agro-industrial waste sustainable management– A potential source of economic benefits to palm oil mills in Malaysia. Journal of Urban and Environmental Engineering, 11(1): 108 - 118.

Loh, S.K., James, S., Ngatiman, M., Cheong, K.Y., Choo, Y.M., and Lim, W.S. (2013). Enhancement of palm oil refinery waste– Spent bleaching earth (SBE) into bio organic fertilizer and their effects on crop biomass growth. Industrial Crops and Products, 49: 775 – 781.

Moshi, A.P. (2017). Characterization of spent bleaching earth and its utilization for improving manure-based biogas production. Biotechnology Journal International, 17(4): 1-13.

Oladosu W.A., Manan Z.A., and Wan Alwi S.R. (2017). Recovery of vegetable oil from spent bleaching earth: state-of-the-art and prospect for process intensification. Chemical Engineering Transactions, 56: 133 - 138.

Oruwari, B.M., Amakiri, A.O., Ogbuji, J.A., and Johnson, N.C. (2000). Metabolizable energy values of whole palm kernel and palm kernel oil sludge using laying hens and adult broiler chickens. Nigerian Journal of Animal Production, 27(1): 64 – 70.

Robani, R.B., and Chan, C. (2009). Reusing Soft Soils with Cement-Palm Oil Clinker (POC) Stabilization. International Conference on Engineering and Education in the 21st Century, Kuching, Sarawak, Malaysia.

Sanawung, W., Cheewaket, T., Tangchirapat, W., and Jaturapitakkul, C. (2017). Influence of palm oil fuel ash and W/B ratios on compressive strength, water permeability, and chloride resistance of concrete. Advances in Materials Science and Engineering, Volume 2017, Article ID 4927640, 8 pages

Sahad, N., Som, A.M., Baharuddin, A.S., Mokhtar, N., Buzu, Z., and Sulaiman, A. (2014). Physicochemical characterization of oil palm decanter cake (OPDC) for residual oil recovery. BioResources, 9(4): 6361 – 6372.