Oil Palm Tree Wastes 4: Uses of the oil palm empty fruit bunch

Published Date: 26th October 2020

Introduction

After harvesting, the fresh oil palm fruit bunches are processed in the oil mill to produce the crude palm oil, and palm kernels. The residue wastes generated from the process are the empty fruit bunches, mesocarp or palm press fibers, shells, palm oil mill effluent (POME), and boiler ash. The empty fruit bunch, palm press fibers, and shell account for 43 - 45 percent of this oil mill residue, while empty fruit bunch constitutes about 20 – 23 percent of the fresh palm fruit bunch. The empty fruit bunch is however currently underutilized and therefore creates major disposal problems for the palm oil milling industry. In many oil palm plantations, the empty fruit bunch is returned to the fields as mulch, and manure or used as fuel in the milling process, with the ash, also being returned to the field as fertilizer. The exponential increase in global palm oil production has however resulted in the production of large volumes of the empty fruit bunch, leading to disposal challenges in large plantations. In these big plantations, there has been a tendency to dispose of the empty fruit bunches without recovering the residual oil in them, a practice that negatively impacts agricultural soil characteristics. Open burning of the empty fruit bunch is also practiced in some plantations and has been shown to cause air pollution and a waste of renewable energy resources. Traditionally in West Africa, the ash derived from the empty fruit bunch is used in the cooking and production of black soap.

The overall principles of waste management are to reduce the volume of the waste, recycle it, recover the energy, and nutrients in it, and finally dispose of it. Thus, the current industry approaches to empty fruit bunch management are not economical and environmentally friendly and therefore have received research attention in recent years, especially in Asia. Generally, for each kilogram of palm oil produced, about one kilogram of wet empty fruit bunch (about 60 percent moisture) that requires some form of drying is also produced. In some oil mills, it may be dried to about 40 percent moisture content before being used as a fuel source for the boiler or other milling processes. It has also been processed as a soil enrichment manure of high nutritional sustainability due to its nutrient release which is particularly suitable for the oil palm, and pineapple plantations. Several studies have also shown that the empty fruit bunch can be processed into excellent fiber, and pulp for the production of thin, high-quality printing papers, photographic papers, security papers, and cigarette wrappers. The empty fruit bunch has also been processed into briquettes of good burning quality as well as activated charcoal and biochar. Plywood and particleboard made from the empty fruit bunch have also been shown to exhibit excellent qualities comparable to plywood produced from conventional wood materials.

Several studies have explored the production of biochemicals such as ethanol, bio-oil, and syngas from an empty fruit bunch as a sustainable alternative to oil palm waste management. Through thermo-chemical transformation, the cellulose, and hemicellulose contained in the empty bunch can be hydrolyzed to sugars, and afterward fermented to produce biofuels, such as ethanol, butanol, biogas, organic acids, and cellulose enzymes among others. A recent study by Hafyan and coworkers proposed the development of an integrated biorefinery for the production of essential chemicals like xylitol, levulinic acid, succinic acid, guaiacol, and vanillin. The empty fruit bunch has also served as an efficient substrate for the production of feed-grade bio-proteins through solid-state bioconversion, employing Aspergillus niger or Trichoderma viride. Other approaches such as fiber cracking technology that combines urea treatment and high temperature, and pressure treatment have been used to enhance the nutritional value of the empty fruit bunch for livestock feeding. The empty fruit bunch has also been converted into pyrolysis oil which is used in gas-fired power plants for electricity generation. The empty fruit bunch is therefore an underutilized biomass resource of enormous economic potential for the production of value-added products like bioethanol, biochar, renewable energy, fiber, manure/fertilizer, and animal feeds among others.

Physicochemical characteristics of the empty fruit bunch

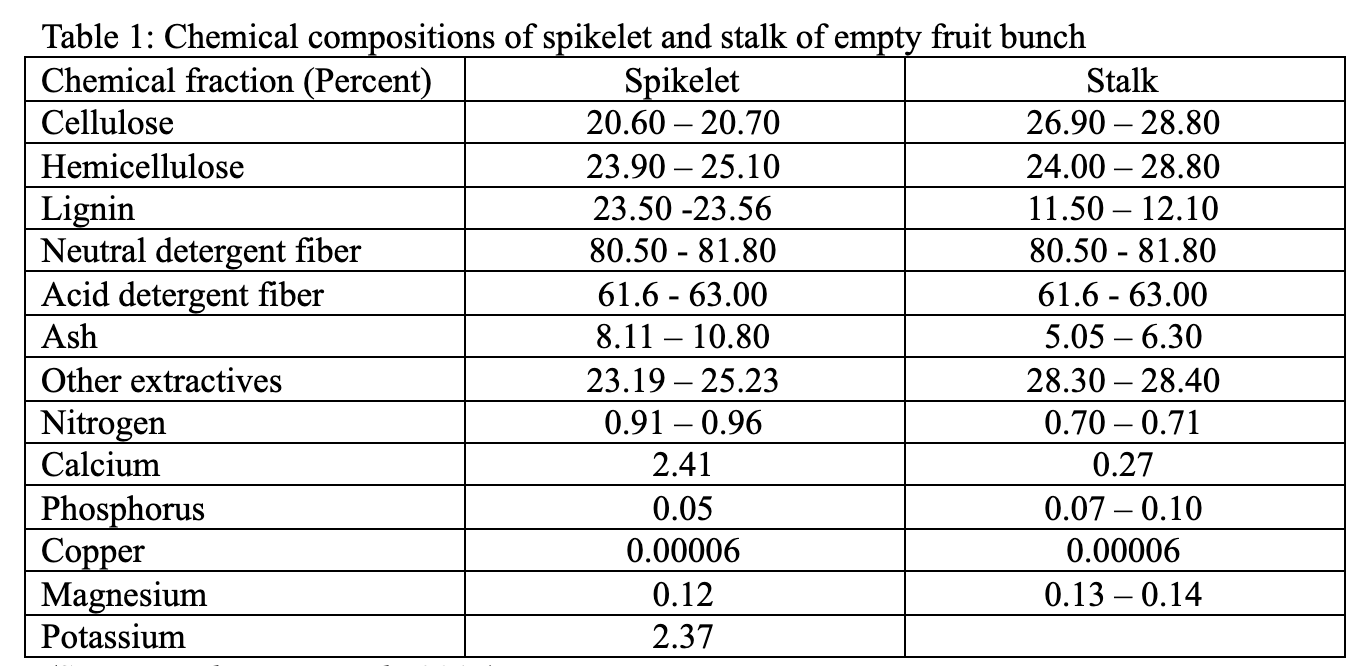

The empty fruit bunch is produced after the fruit bunch stripping process that results in the separation of the fruits from the bunch stalks. Artisanal, and smallholder producers in West and Central Africa usually separate the fruit containing spikelets manually from the stalk before extracting the nuts from the spikelets. In industrial production, the steam sterilization process method employed results in the production of a high moisture content (60 percent) empty fruit bunch that requires pre-drying before it can be used as fuel. The bunch is made up of the main stem called a stalk, and numerous spikelets on its surface. The spikelet (of 20 to 25 percent), and the stalk (75 to 80 percent), are essentially lignocellulosic biomass containing lignin (20.40 percent), hemicellulose (33.50 percent), and cellulose (44.20 percent). The bunch has also been shown to contain 32.90 percent glucan, 22.40 percent xylan, and 1.40 percent arabinan. The compositional values reported in table 1 show that the spikelet contains relatively higher levels of lignin (23.50 to 23.60 percent), while the stalk contains higher levels of cellulose (26.90 to 28.80 percent). The lower lignin content of the stalk confers a nutritional advantage on it when processed for ruminant feeding. The ultimate analysis of the spikelet and stalk fibers has also been reported to yield a carbon content range of 43.62 to 52.68 percent, and a nitrogen content range of 0.69 to 0.96 percent, while the most abundant minerals are potassium and calcium.

Thus, the cellulose, hemicellulose, and lignin content of the empty fruit bunch are variable across the two components and this determines its various applications in the industry. The empty fruit bunch derived from industrial processing also contains a significant amount of residual oil (0.28 to 1.38 percent), which are usually absorbed, and retained in the lignocellulosic material. The quantity of oil entrapped in the lignocellulosic material however depends on the efficiency of the oil extraction process.

Uses of the empty fruit bunch

Traditionally, the empty fruit bunch is burnt in open air reduces the volume or in a burner to generate energy, and produces ash which has some value because of its high potassium, and other mineral contents. In some palm plantations, the ash is recycled to the field to enrich the agricultural soil, while in others, it is discarded in landfills as waste material. The bunch has also been used or sold as mulch and manure in small-scale plantations, however, when discarded in large volumes on the field, its natural degradation produces methane, N2O, and other greenhouse gasses. As a mulch for young palms, the bunch aids the control of weeds, prevents erosions, and maintains soil moisture. It has been reported that burning the empty fruit bunch to generate electricity has better economic benefits than using it as manure. The lignocellulosic fibers in the empty fruit bunch can also be converted into value-added bio-products and chemicals.

Pre-treatment approaches: In most industrial oil mills that use the empty fruit bunch as a fuel source, pre-treatment approaches have been developed to enhance its combustion, since the material contains high levels of moisture, and is characteristically low in bulk density. These approaches include shredding to improve handling, and delivery into the furnace, as well as torrefaction (conversion into a coal-like material), and palletization to improve its combustion characteristics. Shredding has also been used as a pretreatment in producing structural materials like particleboards from the empty fruit bunch. Palletization is used to stabilize and increase the bulk density of the material for extended storage. Some studies have also applied flash pyrolysis of the empty fruit bunch at 400 to 600OC to produce biogas, char, and bio-oil, which are subsequently applied to other beneficial uses. Pre-treatment with sodium hydroxide is used to improve the yield of biogas generated from the anaerobic digestion of the empty fruit bunch. Again, when used as a feedstock for fermentable sugar generation, empty fruit bunch is usually subjected to some chemical (acid, alkaline, and water), and enzymatic pre-treatment that enhances the liberation of the sugars from the fibrous biomass.

Empty fruit bunch as a fiber source: The natural fibers occurring in the empty fruit bunch can be processed for several industrial applications such as material for particle boards, composite panels, reinforced cement-based materials, pulp and paper, soil stabilization, and horticultural applications. The fiber is increasingly used in industries, chiefly because of its availability, renewability, low cost, and verified properties. The fiber has also been used to produce a paper of higher bulk or lower sheet density and considerably higher tear index but of inferior tensile strength when compared to papers made from conventional aspen and hardwood kraft pulps. A brightness of 75 – 80 percent has been achieved by bleaching the pulp with a chlorine-free process.

The empty bunch has been used to produce excellent particle boards. Since the quality of particleboard is determined by the composition, fiber length, fiber orientation, and fiber diameters, the characteristics of the empty fruit bunch is a critical factor to the quality of the particleboards and composite materials produced from it. Particleboard is a wood composite made from particles, derived from waste wood materials from saw-mills such as branches, off-cuts, and sawdust. Indeed, composite fibers (fiber-reinforced composite, fiber-matrix composite, bio-composites, nano-composites) are been developed from the oil palm empty fruit bunches with the objective of enhancing its quality, function, and utility. Thus, particleboards manufactured from the oil palm empty fruit bunches fibers are increasingly being used as a sustainable alternative to the conventional particle board in this era of extensive forest depletion. Researchers at the Universiti Putra, Malaysia reported that the major advantages of particleboards made from oil palm empty-fruit bunch include; a potential substitute for the conventional wood-based particleboard, comparatively lower cost, and greater environmental friendliness, with the low cost being the primary driver of its preference in the market.

Production of bio-oil and co-product: As lignocellulosic biomass, the empty fruit bunch can be converted into oil which can be used to produce biodiesel. The flow diagram of the general process for converting an empty fruit bunch into microbial oil is shown in figure 1. A researcher at the Queensland University of Technology, Australia, investigated the microbial oil production from oil palm empty fruit bunch using Aspergillus oryzae, Mucor plumbeus (fungi), and Rhodotorula mucilaginosa (yeast). The organisms were cultivated on empty fruit bunch substrates subjected to dilute acid pretreatment, followed by enzymatic hydrolysis of the solid residue. The M. plumbeus cultivation resulted in the highest oil concentrations, and yield, while all the oils produced were suitable for biodiesel production, indicating that the material is a potential low-cost raw material for oil production by these microorganisms.

In another study, researchers at the Universiti Teknologi Petronas, Malaysia, utilized the empty fruit bunch to produce valuable biochemicals such as xylitol, levulinic acid, succinic acid, guaiacol, and vanillin at a minimum yield of 96, 67, 73, 33, and 7 percent by weight respectively.

The empty fruit bunch as manure: Some small and medium-scale oil palm plantations process, and sell their empty bunch as manure to farms or for use in their own plantation fields. The bunches may be subjected to size reduction by feeding them into a horizontally mounted shredder that discharges the shredded material into a bin for later collection or by milling with a hammer mill. The desired size will usually depend on the type of soil or growth medium being prepared. A size range of 2 to 10 mm has been proposed by some researchers with the smaller particle size being ideal for preparing top grade soil or growth medium, while the bigger size is preferred when the material is applied as mulch.

The empty fruit bunch can be composted to reduce its volume, and improve its value as fertilizer. However, the composting process takes a longer time (up to 12 months) to mature and therefore can be shortened by adding higher nitrogen sources like a chicken, goat, and cattle manure, and palm oil mill effluent. In a study at the Malaysian Agricultural Research and Development Institute, Kuala Lumpur, Malaysia, researchers, exposed a pile of empty fruit bunch to the weather elements for two months before mixing it with 20 percent chicken manure, and thereafter heaping the blend in a shed, and mixing at monthly intervals. They reported that the compost matured in a shorter time of only four months at a compost temperature of 30°C, and a pH range of 4.5 - 6.0. Other studies have shown that composting with a goat, cattle or chicken manure can yield superior products containing as much as C/N ratio of 14:1, 18:1, and 12:1, respectively, after two months.

The empty fruit bunch has also been used as a substrate for growing edible mushrooms such as the oyster and Ganoderma mushrooms. A study at the Japan Atomic Energy Research Institute, Japan, investigated the use of pasteurized empty fruit bunch as a substrate for the cultivation of mushrooms and reported excellent yield, especially at four weeks’ incubation period. The post-cultivation substrate has also been used to produce biogas by the researchers at the Bogor Agricultural University, Indonesia. Again, composting empty fruit bunch through mushroom production has been used to reduce the volume of the material, although using the empty fruit bunch in mushroom production requires laborious initial preparations such as size reduction by shredding into smaller pieces, and addition of ready to use sawdust.

Utilization of empty fruit bunch as ruminant feed: Several studies have documented the nutrient value, improvement methods, and feeding response of ruminants to sole and blended empty fruit bunch-based diets. Fermentation of the empty fruit bunch with white-rot fungi and inoculation with edible mushrooms have been reported to enhance the degradation of the lignocellulosic substrates by enzymes such as cellulase, hemicellulase, and pectinase to yield products of higher nutrient values, and palatability for ruminants. Researchers at the Japan Atomic Energy Research Institute studied the effect of ƴ-irradiation and combination treatment with alkali on the enzymatic digestibility of empty fruit bunch as a substrate for fungal fermentation. They reported that the ƴ-irradiation enhanced the enzymatic digestibility, and the amount of galacturonic acid, and neutral sugars released from the empty fruit bunch in a dose-dependent manner. A combination of ƴ-irradiation and alkaline treatment resulted in better yields of xylose, and glucose as well as enhanced digestibility of xylan. These researchers also reported in their other studies that irradiation and fermentation treatments reduce the fiber content including crude fiber, neutral detergent fiber, and acid detergent fiber in an empty fruit bunch, thereby improving its digestibility. Cattle fed such fermented products at 33 percent level of inclusion in the diet were found to maintain normal feed intake thus, highlighting the tremendous potential for the utilization of empty fruit bunch in cattle feeding.

Conclusion

The empty fruit bunch is an abundant by-product of the palm oil processing industry currently discarded as waste in many palm oil-producing countries. Emerging studies have however shown that it can serve as feedstock for the production of value-added products such as manure, fertilizers, bio-oil, biochar, fiber products, and animal feeds among others. Most of these technologies have been researched and developed in Asian countries, and therefore need to be adopted in other oil palm producing countries, especially in Africa, in order to conserve this abundant resource, create additional income for producers, and employment for the populace.

Bibliographic references

Abdullah, N., and Sulaiman, F. (2013). The Oil Palm Wastes in Malaysia. In: Biomass now – Sustainable growth and use. Intech Open, http://dx.doi.org/10.5772/55302

Ahmad, F.B. (2016). Microbial Oil Production from Oil Palm Empty Fruit Bunch. Ph.D. Thesis, Queensland University of Technology, Queensland, Australia.

Boschma, S., and Kwant, K.W. (2013). Valorization of palm oil (mill) residues. Identifying and solving the challenge. NL Agency, Utrecht, The Netherlands.

Hafyan, R.H., Bhullar, L.K., Mahadzar, S., Bilad, M.R., Nordin, N.A.H., Wirzil, M.D.H., Putra, Z.A., Rangaiah, G.P., and Abdullah, B. (2020). Integrated biorefinery of empty fruit bunch from the pail oil industry to produce valuable biochemicals. Process, 8: 868; DOI:10.3390/pr8070868

Kume, T., Matsuhashi, S., Ito, H., Hashimoto, S., Ishigaki, I., Awang, M.S., Lebaijurt, M., Othman, Z., Ali, F., Husain, W.B.W. and Hamdani, H. (1998). Study on the upgrading of oil palm wastes to animal feeds by radiation and fermentation processing. Japan Atomic Energy Research Institute, Tokai-mura, Naka-gun, Ibaraki-ken, Japan.

Md Yunos, N.S.H., Baharuddin, A.S., Md Yunos, K.F., Hafid, H.S., Busu, Z., Mokhtar, M.N., Sulaiman, A., and Md. Som, A. (2015). The physicochemical characteristics of residual oil and fibers from oil palm empty fruit bunches. BioResources, 10(1): 14 - 29.

Ratnasingam and K. Wagner, 2009. The Market Potential of Oil Palm Empty-Fruit Bunches Particleboard as a Furniture Material. Journal of Applied Sciences, 9: 1974-1979.