Oil Palm Tree Wastes 5: Uses of the palm-pressed fiber

Published Date: 2nd November 2020

Introduction

In the medium to large-scale industrial palm oil milling operations, the fresh palm fruit bunches are subjected to four stages of processing involving bunch cooking, bunch stripping, oil extraction, and oil refining. While the targeted product is the refined oil, several by-products such as the empty fruit bunch, palm oil sludge, and palm-pressed fiber, are also produced, and maybe discarded as waste or used for other purposes in the mill, and the plantation. The palm-pressed fiber, also known as oil-rich fibrous residue or mesocarp fiber is one of the major fibrous by-products obtained after the extraction of palm oil from the oil palm fruit by means of a screw-press. It is a combination of palm mesocarp fiber, kernel shell, crushed kernel, and debris. It appears as a deep-yellow colored, sweetish smelling, and grease textured material, mostly because of its content of substantial amounts of residual palm oil. In small-scale operations, the palm nuts are cooked, and pressed in a screw mill to obtain the red palm oil, while a mixture of mesocarp fiber and nuts remain in the press as a by-product. The mesocarp fiber and nuts can be separated manually or mechanically, depending on the scale of the operation. Traditional and small-scale oil mills operating with a single mini-screw mill usually carry out manual separation to save cost, although the process is laborious and slow. In the medium and large-scale mills that have large processing capacity, machines are employed to semi-automate and speed-up the separation process. For example, a “depericarper” machine that uses air current to separate the fiber, and the nuts by blowing away the lighter fibers, and allowing the heavier nuts to fall into a nut polishing bin, can process more than 10 tons of the fiber and nut mixture per hour.

It is estimated that about one ton of palm-pressed fiber is obtained from 1800 tons of palm fruit, indicating that a sizable volume of the material is being produced in the oil mills in major oil palm producing countries. The palm mesocarp fiber accounts for 10 – 15 percent of the fresh fruit bunch. The fiber is a bulky, and highly variable material containing some residual oil. It is therefore usually burnt in combination with the palm kernel shell as fuel to provide energy for the palm oil mill. However, the ash obtained from burning the palm-pressed fiber is deficient in essential nutrients, especially potassium. It is therefore sparingly used as soil enrichment fertilizer in the palm plantation. On a limited scale, the palm pressed fiber has also served as raw material for producing palm fillets, palm pellets, palm fiber, and other products. It has been composted with the aid of fungal organisms, and mushrooms to produce manure and animal feed. Its fiber and lignin contents are high and comparable to that of wood, although its low palatability limits its use in animal feed formulation, indicating the need to improve its nutrient value.

The fresh palm-pressed fiber contains between 48 and 52 percent moisture. The moisture content is therefore usually reduced to about 30 percent in order to reduce the handling cost, and improve the combustion characteristics. The palm-pressed fiber also contains 5 - 6 percent residual oil on a dry basis, which could be extracted as crude palm-pressed fiber oil, and used in non-food products because of its relatively poor quality. The crude palm-pressed fiber oil can be used in animal feed formulations or refined into higher-quality fiber oil by eliminating its undesirable components such as gums, waxes, trace metals, and free fatty acids. The palm-pressed fiber has also been used as a reinforcing agent in the fabrication of polymer/fiber bio-composites, as a substrate for culturing mushrooms, growing medium for tissue culture seedlings, and for the production of filters, sugar, lubricants, and other chemicals. Thus, processing of the palm-pressed fiber into these value-added products could serve as an avenue for waste disposal, and also new revenue for both the small, medium and large-scale palm oil mill operators.

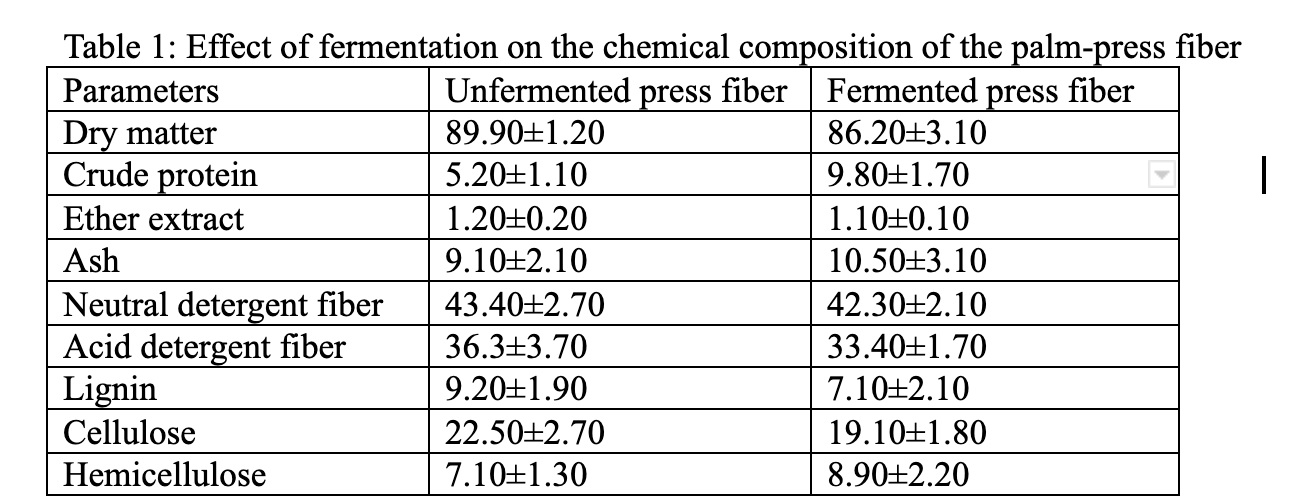

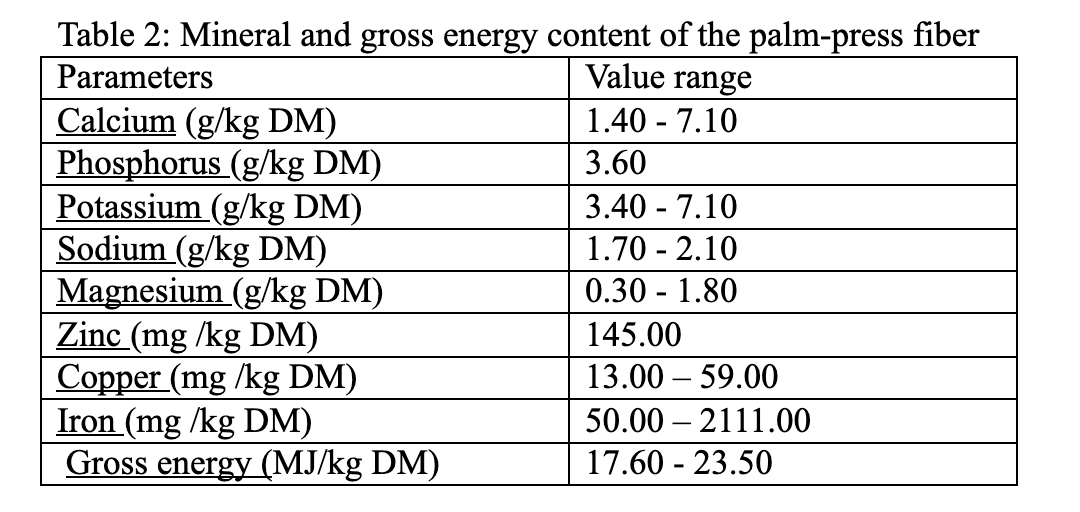

Physicochemical composition of the palm-pressed fiberChemical composition analysis has shown that averagely the palm-press mesocarp fiber contains 59.6 percent holocellulose, 28.5 percent lignin, 1.9 percent lipid, 3.6 percent protein, 5.6 percent ash, and 0.8 percent other chemicals. The cellulose, and hemicellulose, contents have also been reported to average 42, and 32 percent respectively. Researchers at the Sriwijaya University, South Sumatera, Indonesia, evaluate the effect of fermentation with the white-rot fungi (Phanaerochaeta chrysosporium) for 24 hours at room temperature on the chemical composition of the palm-press fiber. The result in table 1 showed that the fermentation was able to increase the crude protein, while the fiber fraction values were reduced, indicating that such treatment could improve the nutrient value of the material. Data in table 2 also showed that potassium, phosphorus, and calcium are the major macro-minerals found in the palm-pressed fiber, while the major micro-minerals are zinc, iron, and copper. The gross energy content of the fiber is however relatively moderate in value.

In a study at the Universiti Putra Malaysia, Serdang, Selangor, Malaysia, researchers treated the palm-pressed mesocarp fiber with superheated steam (190 – 230°C) for 1, 2, and 3 hours, in order to modify its chemical characteristics. Steam treatment at 230°C resulted in a significant decrease in the hemicellulose content from 33 to 9 percent, while silica bodies were also removed, indicating an overall surface modification, and improvements in the chemical characteristics of the palm-pressed mesocarp fiber.

The mesocarp fiber as a component of the palm-pressed fiber also contains 5 – 6 percent residual oil, which has been found to be rich in carotenoids (4000 – 6000 ppm), vitamin E (2400 – 3500 ppm), sterols (4500 – 8500 ppm), and coenzyme Q10 (1000 - 1500 ppm). The lipid values of the palm-pressed fiber oil have also been reported to be 15 - 20 percent diacylglycerol, which serves as a cooking oil in some countries, and 47 – 70 percent triacylglycerol, and small amounts of lauric acid, which serve as a preservative against food spoilage.

Uses of the palm-press fiber

The palm-press fiber is commonly used as a source of fuel for the firing of boilers in the oil mill. Other value addition approaches that have been researched include its potentials as a substrate for mushroom cultivation, soilless medium for growing seedlings, vermicomposting, and use in feeding livestock. The residual oil extracted from the fiber has also been used as feedstock for the production of different industrial, and medicinal biochemicals.

Palm-press fiber as a substrate for culturing mushrooms: The ability of different types of fungi to biodegrade lignocellulosic materials found in numerous biomass residues is predicated on their synthesis of lignocellulolytic or fibrinolytic enzymes such as xylanases, cellulases, and laccases, which they employ in the biodegradation processes for energy generation, and production of novel biochemicals. Thus a wide range of biomass residue wastes such as sawdust, rice straw, bagasse, corn stalks, waste cotton, banana stalks, and root and tuber peels have been used as substrates for the culture, and growth of edible, and medicinal mushrooms. Previous attempts at the cultivation of the oyster mushroom, Pleurotus pulmonarius on oil palm fiber had met with various degrees of difficulties. Some of these residues require some form of enrichment for optimal mushroom yield. For example, earlier studies in Nigeria reported negative growth by P. pulmonarius cultivated on palm-pressed fiber, while limited growth was observed on substrates comprising mixtures of palm-pressed fiber, cassava peel, and sawdust. More recently, however, researchers at the Ladoke Akintola University of Technology, Ogbomoso, Nigeria, revaluated the use of palm pressed fiber for the cultivation of P. pulmonarius by preparing substrates in which sawdust, palm press fiber, and palm press fiber ash were mixed at the ratios of 1:1. They reported that the highest mushroom yields were recorded in substrates containing a 1:1 ratio of palm-pressed fiber, and palm pressed fiber ash, moistened with either water or Hoagland solution, indicating that when appropriately enriched, the palm-pressed fiber can serve as an excellent substrate for the growth of oyster mushroom.

Palm-press fiber as a soilless growing medium: The agricultural potential of the palm-pressed fiber as fertilizer has not been extensively studied. It is however possible to utilize the post-mushroom cultivation substrate as a soilless growing medium. For example, a significant increase in dry weight, and total flower production has been reported for potted ornamental plants grown on palm-pressed mesocarp fiber compost. In a study carried out at the Felda Agricultural Services Sdn. Bhd., Kuala Lumpur, Malaysia, mixtures of palm-pressed mesocarp fiber, compost, and chicken manure as fiber + 20% (v/v) compost, and fiber + 20% (v/v) chicken manure were compared with soil mixtures as a growing medium for banana tissue culture seedlings. The mesocarp fiber mixtures with compost or chicken manure were found to be better-growing media for the banana seedling than the soil mixtures in terms of nutrient uptake, plant growth, protection against pathogens, lighter weight, weed control, and ease of handling and bagging. The study therefore highlights the need for the addition of extra nutrient sources such as compost or chicken manure to the palm-pressed mesocarp fiber intended for use as a seedling growing medium. Researchers at the Citra Widya Edukasi Palm Oil Polytechnic, Jalan Gapura, Indonesia, also used three types of compost made from mixtures of palm-pressed fiber and cow manure at the ratios of 3:1, 1:1, and 1:3 as pre-nursery growing medium for oil palm seedlings, and reported better growth performance of oil palm seedlings in media containing high proportions of the mesocarp fiber.

Vermicomposting of palm-press fiber: Vermicomposting of palm oil mill wastes has been used to convert the wastes into useful plant nutrients, and organic fertilizer. This is because the oil palm wastes decompose slowly under normal condition, therefore soil micro- and macro-organisms are needed to boost the process. In vermicomposting, epigeic earthworms are used to speed up the decomposition time, while producing high quality manure that is low in toxicity, high in nitrogen content, and of greater fertilizer value. Researchers at the Universiti Sains Malaysia, Penang, Malaysia, conducted a 50 days’ study to determine the characteristics of vermicomposts produced with aid of adult Lumbricus rubellus, and from the combinations palm oil mill effluent and palm pressed fiber at 50:50 ratios, palm oil mill effluent/palm pressed fiber/cow dung at 50:25:25 ratios, palm oil mill effluent/palm pressed fiber/cow dung/lawn clipping at 50:20:15:15 ratios, and 100 percent palm press fiber. The addition of cow dung, and lawn clipping to the palm oil mill effluent/palm-pressed fiber helped to stabilize the compost, and accelerate vermicomposting process. Earthworm growth, biomass gain, and vermicompost nutrients were also higher as a result of the addition of cow dung/lawn clipping to the palm oil mill effluent/palm pressed fiber waste.

Use of palm-press fiber for feeding livestock: The abundance of palm-pressed fiber at most palm oil production locations has made it attractive to research its potential as alternative feed raw material. Its widespread use as animal feed is however constrained by low digestibility, and the potential problem of rumen impaction. Earlier studies have shown that the palm-pressed fiber is similar to rice straw in fiber characteristics, while other studies have pointed to its high lignin, and poor digestibility. Several in vitro digestibility studies have therefore been carried out to determine the feeding value of the palm-pressed fiber. Researchers at the University of Science and Technology, Kumasi, Ghana, used the in vitro digestibility technique to determine the feeding value of untreated, defatted, and 5 percent sodium hydroxide treated palm-pressed fiber. The result showed that defatting, and treating with 5 percent NaOH solution significantly improved the dry matter, and organic matter digestibility of the material. In a similar study, researchers at the Universitas Padjadjaran, Jatinangor–Sumedang, India, determined the effect of soaking palm oil fiber in filtrated palm oil fruit bunch ash on in vitro digestibility. Different concentrations of palm oil fruit bunch ash solution (50, 100, 150, and 200 g/liter) were used to soak the palm oil fiber for 3 hours, and thereafter processed and analyzed for their lignin, and crude fiber values. The results showed that treatment with 150 and 200 g/liter of ash solution produced the lowest levels of lignin, while the 150 g/liter ash solution treatment produced a higher level of crude fiber, indicating that soaking in 150 – 200 g/liter ash solution is effective in improving the digestibility of the palm pressed fiber. Other treatments applied to the palm-pressed fiber to improve its digestibility include alkali treatments with calcium hydroxide, steaming at 15 kg/cm2 for 10 minutes, and explosive depressurization at 30 kg/cm2 for 1 minute.

Optimum dry matter digestibility has been reported with 30 percent inclusion of palm-pressed fiber in sheep, and calve diets, while diets containing 50 percent palm pressed fiber, and 30 percent palm kernel cake was reported to be a cheaper source of energy for dairy cattle compared to the conventional starch-based pelleted ration. Researchers at the Sriwijaya University, South Sumatera, Indonesia, evaluated the potential of fermented palm-pressed fiber (fermentation with white-rot fungi for 7 days at room temperature) as a 5 percent supplement to increase in vitro rice straw digestibility. They reported that dry matter digestibility, and crude protein were not improved by treatment, while organic matter, and crude fiber were significantly affected the supplementation. Several Colombian researchers have also reported poor performance in pigs fed palm-pressed fiber supplemented diets although the cost of diet formulation was substantially reduced.

Researchers at the University of Abomey Calavi, Cotonou, Benin also evaluated the optimal inclusion level of palm-pressed fiber in a growing rabbit diet during a six weeks feeding trial. The palm-pressed fiber was included in the diet at 5, 10, and 15 percent levels. They reported that the daily feed intake was not significantly affected by the diet containing up to 15 percent palm-pressed fiber, while the average live weights of the rabbits were similar, indicating that up to 15 percent of palm-pressed fiber can be included efficiently in growing rabbit diet. These reports show that farmers operating in the vicinity of oil palm mills could reduce the cost of feeding by utilizing up to 15 and 30 percent of both fresh, alkaline treated, and fermented palm-pressed fiber in feeding rabbits and ruminants respectively.

Conclusion

The palm-pressed fiber is a by-product derived from the processing of palm fruit bunch, and is a combination of palm mesocarp fiber, kernel shell, crushed kernel, and debris. It has been employed as a reinforcing agent in the fabrication of polymer/fiber bio-composites, as a substrate for culturing mushrooms, growing medium for tissue culture seedlings, and for the production of filters, sugar, lubricants, and other chemicals. It can therefore serve as a source of revenue for both the small, medium, and large-scale palm oil mill operators.

Bibliographic references

Darmawan, A.L., Irawan, A., Dhalika, T., Tarmidi, A.R., Mansyur, Budiman, A., Kamil, K.A. and Hernaman, I. (2014). The study on in vitro digestibility of soaked palm oil fiber by filtrated palm oil fruit bunch ash. Majalah Ilmiah Peternakan, 17(1): 1 – 3.

Fariani, A., Abrar, A., Muslim, G., and Warly, L. (2015). Supplementation of Fermented Palm Press Fibre on Digestibility of Rice Straw and Rumen Bacteria Profile. Pakistan Journal of Nutrition, 14 (2): 80 - 83.

Hoe, T.K. (2014). Utilization of oil palm fruits mesocarp fibers waste as growing media for banana tissue culture seedling in Malaysia. Journal of Advanced Agricultural Technologies, 1(1): 52 – 55.

Houndonougbo, M.F., Chrysostome, C.A.A.M., Attakpa, S.E., Sezan, A., and Dehou, H. B. (2012). Growth performance of rabbits fed palm-press fibers-based diets. ISRN Veterinary Science, DOI:10.5402/2012/915729

Liasu, M.O., Adeeyo, A.O., Olaosun, E.O. and Oyedokun, R.O. (2015). Pleurotus pulmonarius cultivation on amended palm press fiber waste. African Journal of Biotechnology, 14(19): 1624-163.

Nordin, N.I.A.A., Ariffin, H., Andou, Y., Hassan, M.A., Shirai, Y., Nishida, H., Yunus, W.Z.W., Karuppuchamy, S. and Ibrahim, N.A. (2013). Modification of oil palm mesocarp fiber characteristics using superheated steam treatment. Molecules 2013, 18, 9132-9146; doi:10.3390/molecules18089132

Neoh, B. K., Thang, Y. M., Zain, M. Z. M., and Junaidi, A. (2011). Palm pressed fibre oil: A new opportunity for premium hardstock? International Food Research Journal, 18: 769-773.

Rupani, P.F., Ibrahim, M.H. and Ismail, S.A. (2013). Vermicomposting biotechnology: recycling of palm oil mill wastes into valuable products. International Journal of Recycling of Organic Waste in Agriculture, 2:10 http://www.ijrowa.com/content/2/1/10

Obese, F.Y., Osafo, E.L.K. and Okai, D.B. (2001). Evaluation of feeding value of palm press fiber using in vitro digestibility technique. Tropical Animal Health and Production, 33: 165 – 172.