Oil Palm Tree Wastes 9: Palm kernel meal production and nutrient composition

Published Date: 30th November 2020

Introduction

The processing of oil from palm fruit results in the production of palm oil and nuts. When cracked, the nuts yield the edible endosperm or palm kernel seed which is rich in energy due to their oil content. Palm kernel seed or nut contains about 46 – 54 percent oil on a dry matter basis, and has a high gross energy content of about 28.9 MJ/kg. The nut constitutes a major component of the diet of many Nigerians, especially in the rural areas where it may be eaten raw or boiled. In the oil mills, the kernel seed is further crushed to extract the palm kernel oil, while the residue remaining from the process is called palm kernel meal or cake, depending on the extraction method employed.

Globally, palm oil, and palm kernel oil are currently the two major vegetable oils used in household cooking, and several industrial applications. Because of the industrial uses, and export potentials of palm kernel oil, palm kernel meal, and cake are readily available in large quantities at palm oil processing factories. Different extraction methods such as mechanical extraction, solvent extraction, prepressing followed by protein extraction, hydrothermal techniques, and supercritical carbon dioxide extraction have been used to process the kernel nuts into palm kernel oil, and palm kernel meal or cake. The mechanical method, which uses an expeller to extract the oil results in the production of the palm kernel cake (PKC), while the other methods yield the meal (PKM). The term “palm kernel meal” is however adopted in this chapter as the general name for two products. The global production of PKM exceeded 9.5 million metric tons in 2017, with Indonesia and Malaysia accounting together for about 80 percent of the global figure. The estimated annual national output for Nigeria, Ghana, and Ivory Coast were 75,000, 56,000, and 53,000 metric tons respectively, thus making them the leading producers of PKM in sub-Saharan Africa.

The oil extraction method, palm kernel source, efficiency of oil extraction from the kernel, and the residual endocarp have been shown to influence both the chemical, and nutrient compositions of PKM. In recent years, PKM has become an extensively used raw material in the formulation, and manufacture of animal feeds because of its relatively low cost and availability. Based on this, PKM is now regarded as a valuable by-product of palm kernel oil processing, rather than a waste product. For example, PKM is increasingly used to partially substitute for feed ingredients such as soybean, and maize in ruminants, poultry, swine, and freshwater fish diets. Indeed, in West Africa, PKM is being promoted as a potential solution to the pastoral conflicts associated with the dwindling grazing lands, and natural fodder in the sub-region.

Although PKM is also used as a source of bioactive antioxidant peptides, its protein isolates have not found ready application in human foods. Research efforts are however on-going on the physicochemical properties of the proteins in order to successfully incorporate them into human food, and other industrial products. The search for bioactive peptides in PKM is also making possible the extraction of other functional products of high value. For example, peptides of variable molecular weight, and antioxidant activity have been obtained after hydrolysis of the PKM with different proteases such as trypsin, flavourzyme, chymotrypsin, bromelain, alcalase, pepsin, and papain.

Physicochemical characteristics of PKM

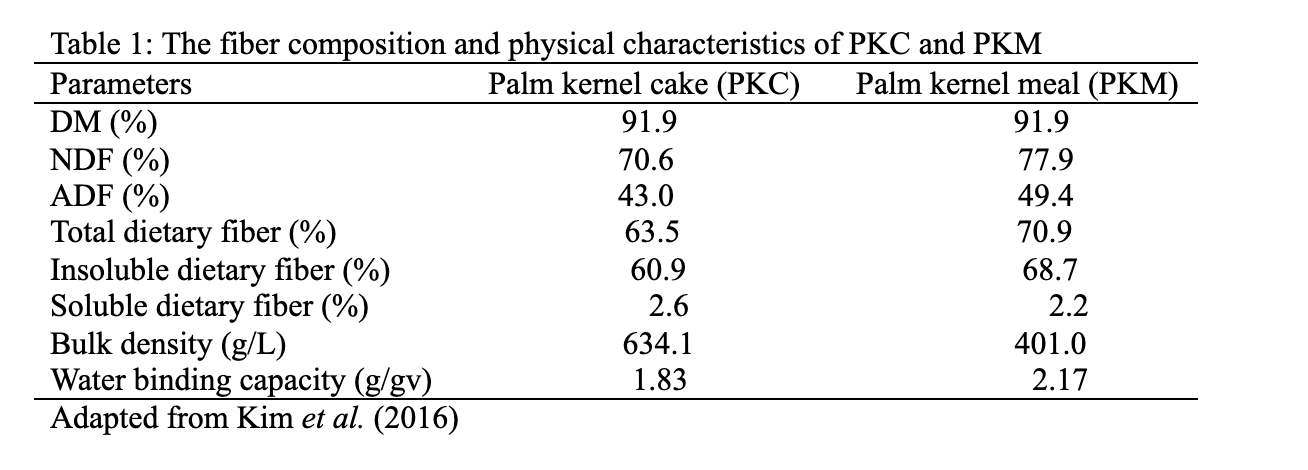

The peculiar physicochemical nature of PKM, especially its grittiness due to high content of lignin and contamination with nutshell, influence its different uses, and industrial application. Very little information exists in the literature on the physical characteristics of PKM, while random analyses have resulted in a wide range of chemical values. Researchers at the Federal University Technology Owerri, Nigeria, in their study on the physical characteristics of PKM, reported 0.36 g/m3, 1.29 g water/g feed, and 0.36 as the bulk density, water holding capacity, and bulk density respectively. As the particle size of the PKM decreases, the water holding capacity increases, while the bulk density and specific gravity decrease. They, therefore, recommended the maintenance of particle size of ≥ 1.00 mm in order to achieve consistency of physical characteristics when using the PKM as a feed raw material. The main component of PKM as a plant by-product is the cell wall, composed of protein, lignin, and carbohydrates, which have been shown to contribute to its physical characteristics. The major polysaccharides occurring in PKM are cellulose, xylans, mannans, xyloglucans, lignin, and extensins. Some of these are members of a group of heterogeneous compounds of non-α-glucan polysaccharides referred to as non-starch polysaccharides (NSP). PKM contains about 60 to 80 percent NSP, which is concentrated more in the endosperm than the endocarp fraction. The high NSP content of PKM, limits its use in monogastric animal nutrition. PKM as a fibre, contains 78 percent hemicellulose in the form of mannan, and 12 percent cellulose. The neutral detergent fiber, and acid detergent fiber could be as high as 77.9, and 49.4 percent respectively. The metabolizable energy varies from 6.19 – 9.46 MJ/kg, and is influenced by the method employed in extracting the palm kernel oil. Usually, the higher value is associated with the oil content of the meal sample, which explains the higher values recorded in the press cake than the solvent extracted meal. The fiber composition, and physical characteristics of PKM, and PKC are shown in Table 1. The meal is generally higher in all-fiber fractions, and water binding capacity than the cake, which has higher bulk density than the meal.

The crude protein content of PKM ranges from 14 to 21 percent. The meal however contains more crude protein than the cake, but less fat, and energy. The amino acid content of PKM is also low, especially the essential amino acids, however, it is an excellent source of arginine. It is therefore important to supplement extra methionine, and lysine in the livestock diet when PKM is included in large quantities. Again, the use of PKM in poultry and other monogastric diets is constrained by the high content of poorly digestible NSPs, low protein digestibility, and absence of limiting amino acids such as lysine, methionine, and tryptophan. The microbial degradation of fibers in the rumen however enables ruminants to utilize PKM better than monogastric animals.

Enhancement of the nutrient value of palm kernel meal

Earlier attempts at incorporating PKM directly into monogastric animal diets, met with limited results, due to its fibrous, and gritty nature. Different physical, chemical, and biological methods have been used to enhance the nutritive value of PKM for monogastric animal feeding, with chemical, and biological methods being the most promising. Physical treatment approach such as extrusion that applies hydrothermal processes with high shear force that enables the disruption of the components of PKM has been used to enhance the nutritive value of PKM within a shorter time than other methods. Researchers at the Universiti Putra Malaysia, Selangor, Malaysia, subjected PKC to such a physical treatment by means of extrusion, in order to reduce its indigestible polysaccharides levels, and reported significant increases in mannose, fructose, and sucrose contents, and decreases in the crude fiber, and total NSP contents. They also reported that the increase in the mannose content was characterized by significant elevations of its mannobiose, mannotriose, mannotetraose, and mannopentaose fractions, with significant decreases in the water holding capacity, and an increase in swelling capacity of the extruded product. Solvent extracted PKM has also been pelleted to improve its bulk density, intake, handling, and transportation.

Palm kernel meal can be delignified with the aid of chemical alkaline or acidic agents such as acetic, and formic acids. About 55 – 60 percent protein concentrate yield has been produced through NaOH (30 – 60 mM) treatment at 35 – 45°C, followed by precipitation with HCl at pH 3.5. Saline solution (200 – 400 mM NaCl, pH 7 – 9) treatment, and drying at 50°C have been found effective, while isoelectric processes are also widely used. Lignin degradation has been achieved with the aid of acid solutions, with increasing concentration of the acid resulting in better lignin degradation.

Biological methods such as solid-state fermentation with cellulolytic fungal, and bacterial cultures in order to increase the protein value, and the availability of nutrients have been applied to the PKM. For example, increases in mannose content of about 6 folds as a result of degradation of the β-mannan in PKC with Aspergillus flavus, and decreases in overall cellulose content of the PKC from 28.30 to 12.10 percent when treated with Trichoderma longibrachiatum, and hemicellulose content from 37.0 to 19.0 percent when fermented with A. niger have been reported. Researchers at the Universiti Putra Malaysia, Selangor, Malaysia, used four cellulolytic and hemicellulolytic bacterial cultures to determine the optimum time period required for solid-state fermentation of PKC, and the effect of combinations of these cellulolytic, and hemicellulolytic bacteria on the nutritive quality of the PKC. They reported that the bacterial cultures exhibited the enzyme activities by the 4th day of fermentation, and declined to zero by the 8th day. Similarly, the hemicellulose, and cellulose content of the PKC decreased significantly, while the reducing sugars content increased in the fermented PKC.

In another study at the Strategic Livestock Research Centre, Kuala Lumpur, Malaysia, researchers evaluated the nutritional improvement, especially protein quality of Aspergillus niger-fermented PKC. The sterile PKC substrate, and 0.5 percent inoculum of A. niger spores was moistened with distilled water to obtain a 50 percent moisture content, and incubated at 300C for 66 hours. Proximate, and chemical analyses of the end product showed an improvement in the nutritional quality of the PKC due to the fermentation process compared to untreated PKC. The crude protein increased from 17.5 to 24.7 percent, while total amino acid, and essential amino acid increased from 14.85 to 15.67, and 6.98 to 7.42 percent respectively. The other effects of the fermentation process are shown in table 2.

Commercially produced enzymes, and multi-enzyme complexes produced from fungi such as Aspergillus niger, Trichoderma. viride, Rhizopus stolonifera, and Mucor mucedo have also been used to improve the nutrient quality, and feeding value of PKM. Researchers at the Universiti Putra Malaysia, Serdang, Malaysia, studied the effects of enzyme treatment on the chemical compositions, and production of reducing sugars from PKM of 80 percent moisture content incubated at 55°C for 18 hours. Crude protein, and gross energy values of the fermented product were not significantly affected by the enzyme treatment, while ether extract, neutral detergent fiber, acid detergent fiber, hemicellulose, and cellulose contents decreased by approximately 34.6, 26, 20, 35.7, and 22.1 percent respectively. The total content of reducing sugars (mannose, glucose, and galactose) increased by approximately 200 folds, while cellulase and mannanase activities in the PKM also increased significantly. Other treatment approaches involving chemical pre-treatment followed by solid-state fermentation have also been extensively explored, and have been shown to produce better results than either chemical or fermentation methods. For example, Mirnawati and coworkers explored the chemical treatment of PKM using humic acid before solid-state fermentation, and reported improvements in the crude protein, and reduction in crude fiber content.

Production of value-added products from PKM

Several bioactive, and value-added products have been developed through microbial conversion processes. Different fungal, and bacterial organisms have been used to convert PKM into bio-ethanol, bio-butanol, and enzymes, because of its high content of hexose sugars. Other products such as cellulose, peptides, and prebiotics have also been produced from PKM. The solid-state fermentation process that uses Saccharomyces cerevisiae as a fermenting organism under low temperatures conditions has been employed as a low-cost bioethanol production method from PKM. For example, Jørgensen and coworkers reported 84 percent conversion of mannan, and glucan in PKM during 216 hours of solid-state fermentation to generate 200 g of ethanol from a kilogram of PKM. Again, PKM can serve as a lignocellulosic substrate for biobutanol production in an acetone-butanol-ethanol (ABE) fermentation process, usually by converting mannose sugar or glucose to butanol. Bio-ethanol, and bio-butanol have emerged as biofuel resources of global importance, although bio-butanol may process certain advantages such as high efficiency, and ease of blending with gasoline over bio-ethanol.

Both β-mannanase, and xylanases have also been produced from PKM through the solid-state fermentative action of different bacterial, and fungal species such as S. cerevisiae, Trichoderma spp, Bacillus spp, Cryptococcus spp, Aspergillus spp, Penicillium spp, Aureobasidium spp, and Fusarium spp, among many others. The production of β-mannanase from PKM using A. niger has been extensively reported in the literature. Again, peptides having antimicrobial activities against Bacillus species, and other spore-forming bacteria have been derived from PKM-protein, and are being employed in the development of novel antimicrobial drugs. The liquid-phase oxidation process has been employed in the extract of the abundant cellulose in PKM for use in the food, pharmaceutical, paint, and polymer industry among others.

It has been recently established that the mannose and mannan-oligosaccharides present in PKM could function as prebiotics in poultry, and livestock nutrition. For example, Rezaei and coworkers recently reported that at 1 percent inclusion of a commercial PKM derived prebiotic, OligoPKE in broiler chicken diets, enhanced feed conversion ratio, increased plasma IgA level, and decreased heterophil, and basophil counts, indicating improvements in immune responses, especially at a younger age when the immune system is still not fully developed.

Conclusion

Palm kernel meal is now regarded as a by-product derived from the processing of palm kernel oil rather than a waste material because of its novel applications in animal nutrition, and production of different value-added products. Its high fiber, moderate protein, and gritty nature however demand that it be subjected to different physical, chemical, and biological treatments in order to enhance the nutritive value for monogastric animal feeding. Recent research activities have resulted in the development of several bioactive, and value-added products such as bio-ethanol, bio-butanol, enzymes, cellulose, peptides, and prebiotics from palm kernel meal.

Bibliographic references

Alshelmani, M.I., Loh, T.C., Foo, H.L., Lau, W.H., and Sazili, W.Q. (2014). Biodegradation of palm kernel cake by cellulolytic and hemicellulolytic bacterial cultures through solid-state fermentation. Scientific World Journal, 2014, http://dx.doi.org/10.1155/2014/729852

Jørgensen H, Sanadi AR, Felby C, Lange NEK, Fischer M, Ernst S (2010) Production of ethanol and feed by high dry matter Hydrolysis and fermentation of palm kernel press cake. Appl. Biochem. Biotechnol., 161: 318 – 332.

Kim, S.A., Kim, B.H., Kim, Y.H., Jung, S., Kim, Y.H., Park, J.C., Song, M.H., and Oh, S.N. (2016). Value of palm kernel co-products in swine diets. Korean Journal of Agricultural Science, 43: 761-768.

Marini AM, Ayub MY, Abd. Salam B, Hadijah H, Azahan EAE, Tarmizi SA (2008) Protein quality of Aspergillus niger-fermented palm kernel cake. J. Trop. Agric. and Fd. Sci., 36(2): 000–000

Omede, A.A., Okoli, I.C., and Uchegbu, M.C. (2011). Studies on the physical characteristics of some feed ingredients in Nigeria 1: Protein sources and industrial by-products. Online J. Anim. Feed Res., 1(5): 190-197.

Rezaei, S., Jahromi, M.F., Liang, J.B., Zulkifli, I., Farjam, A.S., Laudadio, V., and Tufarelli, V. (2015). Effect of oligosaccharides extracts from palm kernel expeller on growth performance, gut microbiota, and immune response in broiler chickens. Poultry Science, 94: 2414 – 2420.

Roslan, M.A.H., Abdullah, N., Murad, N.Z.A., Halmi, M.I.E., Zulkifli, I. and Mustafa, S. (2017). Optimization of extrusion for enhancing the nutritive value of palm kernel cake using the response surface methodology. BioResource, 12(3): 6679 – 6697.

Saenphoom, P., Liang, J. B., Ho, Y. W., Loh, T. C., and Rosfarizan, M. (2011). Effect of enzyme treatment on chemical composition and production of reducing sugars in palm (Elaeis guineenis) kernel expeller. African Journal of Biotechnology, 10(68): 15372 – 15377.