Oil Palm Tree Wastes 6: Uses of the palm kernel shell

Published Date: 9th November 2020

Introduction

In industrial-scale palm oil mills, every 100 tons of palm fruit bunch processed yields about 22 tons of crude palm oil, and about 4 tons of palm kernel, while the remaining 74 tons end up as by-products, and wastes during different stages of the milling process. The two major solid wastes produced from the processing of the fresh palm nuts are the palm kernel shell, and the palm-pressed fiber. The palm kernel shell is the hard fibrous material that encloses the nut or seed of the palm kernel fruit. It is obtained as a residual waste from the cracking of the palm kernels, and extraction of the nuts in the mill, and constitutes about 34.5 percent of a single ripe fresh palm fruit. After processing the kernels, shells usually occur in large, and small fractions, mixed with some fiber, residual oil, and dust depending on the processing method. Traditionally, palm kernel shell is used by palm oil mills as a relatively cheap source of biomass fuel because of its high energy content, while the ash produced from its burning is recycled as fertilizer, and factory floor cleaning agent. The shell has also been used as grit on palm plantation roads to improve vehicular traction where there are no tarred roads. Some artisanal users such as blacksmiths may buy some of the shells to use as fuel material in their furnace. Palm kernel shell is also being exported by some industrial-scale palm oil producers in Asia, while in Africa it is basically considered a waste product which could constitute disposal, and environmental challenges any time production outstrips demand.

Most large-scale palm oil mills in Asia have utilized a combination of the kernel shells, and mesocarp fibers to generate their energy needs, and sometimes for the neighboring communities, usually by means of steam run turbines. As a biofuel, palm kernel shell has a high calorific value of approximately 4000 Kcal/kg, as well as low content of ash, and sulphur. These properties have made it an attractive renewable energy fuel source of considerable export potential in recent times. For example, Malaysia and Indonesia with a combined production estimate in excess of 15 million tons per year, export palm kernel shells regularly to Europe, Japan, and South Korea, mostly by ships in order to reduce transportation costs. It has been projected that palm kernel shell exports from these countries alone can drastically reduce the dependence on wood-based biofuels, thereby protecting forests in the destination countries. Again, new policies that incentivize the biomass fuel use in industries has triggered increased domestic demand for palm kernel shell as an alternative fuel by industries in Indonesia and Malaysia, indicating that exports from these countries may not be sustained in the near future. Perhaps, major palm kernel shell producers in Africa could fill this attractive export niche, if they can meet the key export specifications of moisture content, calorific value, shell hardness, and impurities or contaminants.

Added to its major application in energy/fuel production, palm kernel shell is also being processed as fuel briquettes, biochar, and activated charcoal. It is also being used in construction for concrete reinforcement, aggregate and additive, water purification, fillers in road construction, and production of ash for agricultural and other industrial uses. Recently, the potential value of the palm kernel shell derived activated charcoal, and ash in animal nutrition was reported by researchers at the Federal University of Technology Owerri, Nigeria. Thus, as the global biomass economy becomes increasingly important, new technologies that further enhance the economic value of the palm kernel shell, especially those that improve the combustion characteristics, and increase the energy density would receive research attention. The leading oil palm producing countries in Asia, and Africa could adopt these emerging technologies to exploit the abundant palm-kernel shells for renewable energy and other industrial applications, thereby reducing the current dependence on imported, and non-renewable alternatives and also promoting, and enabling local, and national economies.

Physicochemical characteristics of the palm kernel shell

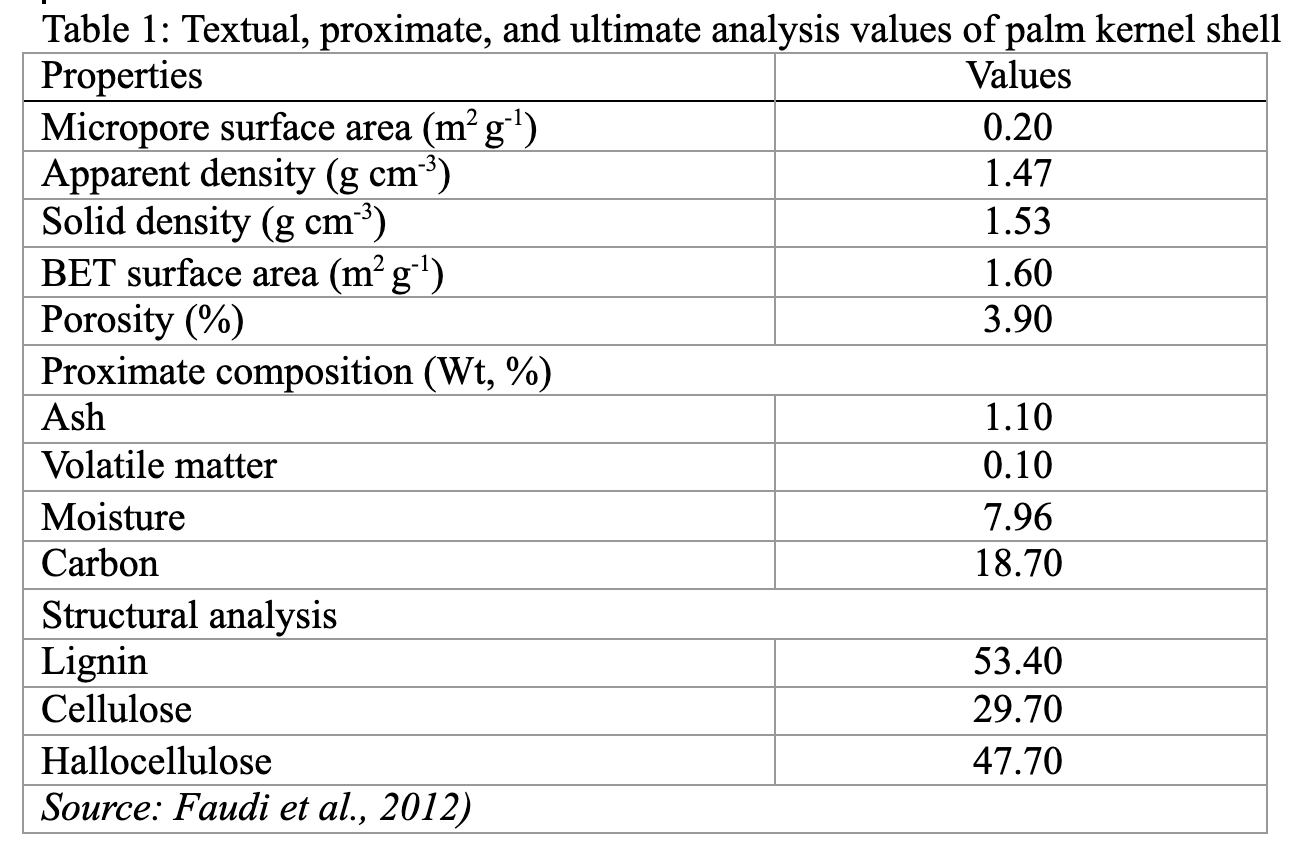

There is a need to determine the actual physical, chemical, and thermal properties of biomass material in order to establish its most appropriate industrial applications. The palm kernel shell has been described as a natural pellet of unique properties that make it useful for different applications. It is a fibrous material composed mainly of lignin, and hemicellulose. It also has a moisture content range of 6 – 9 percent, and appreciable bulk density. The 54 percent lignin content is significantly higher than that of other shell residues like a coconut shell. The textual characteristics, proximate composition, and ultimate analysis of the palm kernel shell are shown in table 1. It has been reported that the level of pulverization of the shell influences the volume, surface area, particle size, pore size distribution, and other properties, and morphology of the shell. The elemental composition values of the shell are also influenced by the pulverization process.

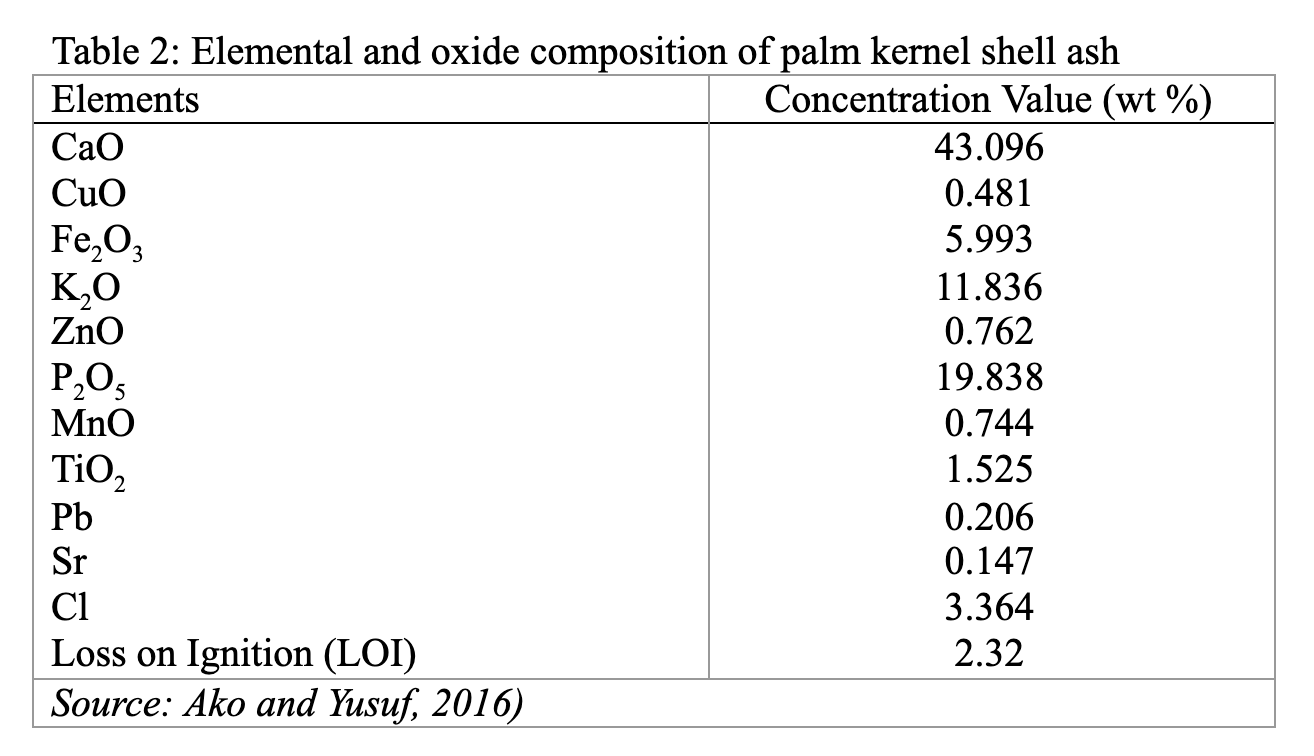

The heating value or calorific value of the palm kernel shell ranges from 24457.96 – 26541.20 KJ/Kg. The heating value of a fuel source is of practical importance since it is the basis for its comparison with other fuel types. It has been reported that the heating value of palm kernel shell is higher than those of firewood, peat, and lignite, but similar to that of bituminous coal. The elemental composition of the palm kernel shell is highlighted in table 2, and shows that the major oxides in its ash are calcium, phosphorus, potassium, iron, and chloride.

Palm kernel shell has been shown to have several advantages over other biomass materials that lend it to exploitation, especially as a biofuel resource. These advantages according to BMC bioPOWER (2013) include; high calorific value, very low ash content, stable moisture content, non-absorbability, resistance to crushing during long-distance transportation, constant granulation curve, advantageous apparent density, ease of blending with coal dust, and resistance to atmospheric conditions. Again, it has been estimated that for every ton of palm kernel shell used as biofuel in place of fossil fuel, about a 0.94-ton reduction in CO2 emission, which is a significant reduction in greenhouse gas emission is achieved.

Uses of palm kernel shell

The usage, and industrial applications of the palm kernel shell could be categorized into three major sections such as energy/fuel production, aggregates for concrete reinforcement, and water purification. The palm kernel shell has also been carbonized to produce activated charcoal, and biochar, which have been used in agriculture, medicine, water treatment, pollutant control. Again, the ash derived from the complete combustion of the palm kernel shell has been applied to engineering, and agricultural soils to enhance their characteristics. The ash has also been used as a mineral additive in animal diets, and substrate for growing crops and mushrooms. The bulk of the palm kernel shell is however increasingly being utilized as a renewable energy source because of its superior combustion characteristics, uniform size distribution, ease of handling, and low greenhouse gas emissions.

Use of palm kernel shell for biofuel/energy production: A large export market has developed in recent times for palm kernel shell as an alternative to the fossil fuels implicated as major sources of atmospheric pollution. Besides the bulk demand for raw palm kernel shells, there is also increasing demand for processed kernel shell products such as partially carbonized, and briquette shells that exhibit superior combustion characteristics. Usually, the palm kernel shells are pulverized to improve their burning efficiency in industrial settings. Therefore, industrial size impact crushers that could pulverize more than 80 percent of the palm kernel shell to 3 mm, and 20 percent to <5 mm particle size are now commercially available. This has made the substitution of a significant percentage of coal for palm kernel shell possible in cement kilns, foundry furnaces, and palm oil mill burners. Biodiesel, and syngas used in burners, and turbines have also been produced through the gasification of palm kernel shell.

Gasification is a process in which biomass is converted under limited air conditions into gaseous fuel containing mainly carbon monoxide, and hydrogen, which are subsequently combusted to produce heat, carbon dioxide, and water. A study at the Universitas Sebelas Maret, Surakarta, Indonesia, used a gate-to-gate approach to evaluate scenarios of palm kernel shell gasification to produce hot-mixed asphalt. In this study, the gasification of palm kernel shell produced both CO, H2, and CH4 as combustible gases, and CO2 as non-combustible gas. A comparison of the direct combustion of diesel fuel, and palm kernel gasification systems for the production of 1 ton of asphalt showed that 41.76 and 63.60 kg CO2 equivalents were generated respectively. It was however calculated that overall, the gasification system decreases greenhouse gas emissions significantly by as much as 40.38 percent for every ton of asphalt produced, because PKS is considered a carbon-neutral resource.

Researchers at the University, Nakhon Si Thammarat, Thailand, also investigated the gasification of palm kernel shells to produce syngas used in the generation of renewable energy and also the conversion of waste from palm oil production to value-added products. A downdraft gasifier that processes 1 kg of palm shell per batch was utilized to produce the syngas samples, which were collected at 15, 25, 35, 45, and 60 min during a 1-h processing period after filtering through biochar in the gasification unit. The results showed that the amount of tar captured in the filter unit was significantly increased up to nine times compared to the system without biochar, indicating a significant tar reduction of the syngas.

Palm kernel shell has also been partially carbonized, and compressed into heat efficient briquettes, of similar calorific value to coconut shell. Other technologies such as torrefaction have also been used to further improve the combustion characteristics, and energy density of palm kernel shells. Torrefaction has been defined as a pretreatment process used to improve the combustion properties of biomass, especially high lignin-containing materials like the palm kernel shell for more efficient energy generation. Nigerian researchers at the Scientific Equipment Development Institute, Enugu, torrefied palm kernel shell under different temperatures (200, 220, 240, 260, 280, and 300ºC), and time (40, 80, 120 minutes) using a horizontal tubular type reactor made of stainless steel, to improve its properties as a solid fuel.

An increase in torrefaction temperature resulted in a decrease in the mass, and energy yield of the palm kernel shell, while the carbon content increased. After torrefaction, the ash, and fixed carbon contents of the palm kernel shell increased with a reduction in the moisture, and volatile matter contents, while hydrogen, and oxygen content decreased, resulting in a higher heating value of 5 to 20 percent. The study, therefore, shows that torrefaction can be used to improve the heating value of the palm kernel shell as a solid fuel.

Palm kernel shell as aggregate for concrete: Palm kernel shell can be processed into various dimensional grades to suit specific applications such as lightweight aggregate for concrete, and fillings. Specifically, the bulk density of the palm kernel shell at 740 kg/m3 is similar to those of other lightweight concrete materials, indicating that the shell could be used as lightweight coarse aggregate. The technical qualities that lend the palm kernel shells for use as concrete mixing material include their relatively low weight, and are natural small size, relative hardness, and organic origin, and non-toxic effects on the concrete. Several Nigerian studies have reported that most buildings constructed with palm kernel shell concrete have an apparent good record of service of more than 30 years.

However, Gibigaye and Godonou in their 2018 study, maintained that most mixed design methods for palm kernel shell concrete that satisfy the requirements of technical specifications for structural lightweight concrete were based on trial, and error or on empirical methods. This is because, mix designs based on the established construction methods for normal, and lightweight structural concrete with mineral aggregates have been unsuccessful. Based on this, they investigated a trail mix proportioning of structural lightweight concrete using palm kernel shell as coarse aggregate. They reported the optimal mix proportions to be C: S: PKS in weight of 1:1.60:0.96 and 1:1.53:0.99 with a cement content of 450 kg/m3 and w/c = 0.45, which resulted in attaining the appropriate values for workability (≥ 20 mm), density (1800 ≤ d ≤ 1900 kg/m3), and cylindrical compressive strength (≥ 15MPa), recommended by ACI and British Code for structural lightweight concrete. The use of palm kernel shells in cement concrete could indeed serve as a sustainable means of converting this abundant waste to more beneficial functions, especially at rural palm oil processing locations, in Africa. This could further reduce the cost of constructing houses, especially at locations where the conventional aggregates are costly.

Use of palm kernel shells for water purification: Palm kernel shells have been employed in the filtering of effluents from sedimentation tanks of water treatment plants, usually in a dual filtration unit composed of fine sand, and palm kernel shells. Water derived from such palm kernel shell effluent treatment although low in turbidity, was tainted by palm nut odor, and taste. Since the use of palm kernel shells for water treatment is predicated on its functional chemistry, and surface composition, there is the need to characterize any given sample to determine its suitability for treating different types of wastewater. Agricultural wastes such as palm kernel shells have been used as adsorbents of heavy metal ions since they can form complexes, and chelates with these metal ions. This absorbance of heavy metal ions involves essentially the complexations, chelation, chemisorption, diffusion through pores, and adsorption on the surface.

Researchers at the University Putra, Malaysia, utilized the palm kernel shells as an adsorbent for the treatment of heavy metal contaminated water. The effects on parameters such as pH of the solution, the concentration of metal ions, adsorbent dosage, and contact time were determined. The results showed that only two hours of treatment was needed to remove heavy metal ions such as Cr6+, Pb2+, Cd2+, and Zn2+ from the water, with percentage removal being 98.92, 99.01, 84.23, and 83.45 respectively.

Use of palm kernel shell for the production of activated charcoal, and biochar: Palm kernel shell is a very good precursor for the production of activated charcoal or biochar, chiefly because it is high in carbon (51.6 percent), and therefore guarantees a high percentage of char product yield. Palm kernel shells can also be carbonized to remove part of the moisture and organic matters that hinder its combustion thereby producing fuel with a smokeless flame, which could be used for non-ferrous firing. Palm kernel shell has also been pyrolyzed to produce 56.6 percent bio-char, 16.67 percent pyrolysate or distillate, and 26.16 percent gas. Researchers at the Universiti Teknologi Mara, Perlis, Malaysia, successfully produced a high quality activated charcoal from palm kernel shell through a single step potassium hydroxide activation, and activation temperature of 800°C. The activated charcoal had a carbon content of 61.10 percent, which was higher than the 47.28 percent recorded in the raw material. The KOH activation also resulted in the creation of numerous pores, and the elimination of volatile compounds from the palm kernel shell during the carbonization, and activation processes.

Researchers at the Malaysian Palm Oil Board, Kajang, Selangor, Malaysia, carbonized palm kernel shell under all thermal conditions at a temperature range of 400 to 600°C, and residence time of 30 and 60 minutes. The biochar yield was found to decrease from 52.1 percent at 400°C (30 min) to 33.4 percent at 600°C (60 min), while pH, elemental, and fixed carbon contents increased with temperature, and residence time. The palm kernel shell derived activated charcoal, and biochar is used in several agricultural, and industrial applications such as compost additive, soil amendment, fertilizer, animal feed additive, water purifier, bleach, and poison antidote among many others. Specifically, palm kernel shell derived biochar has been used to improve the growth rate, and monthly production of mushroom. For example, Nam and coworkers reported a shorter time for mycelium growth, and the highest yield of Oyster mushroom (550 g) when 20 g of palm kernel shell derived biochar was added to the cultivation medium.

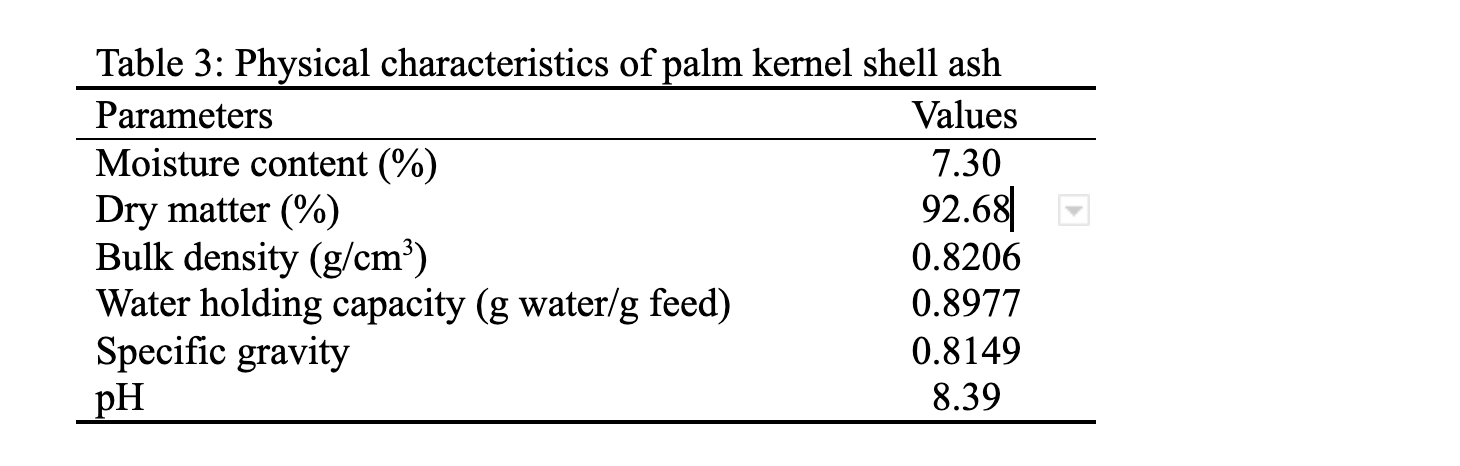

Uses of palm kernel shell derived ash: Palm kernel shell ash is the end product of open-air burning of palm kernel shell. A comprehensive study of the characteristics of palm kernel shell ash at the Federal University of Technology Owerri, Nigeria reported a yield of 24 percent, a pH of 8.39, and among other physical characteristics highlighted in table 3. The study also reported the order of mineral elements in the ash to be K> Mg> Ca> P> Na> Fe> Mn> Zn> Cu, indicating that potassium, magnesium, calcium, and phosphorus were the major minerals found in the ash. The elemental oxides composition of the palm kernel shell ash has also been presented in table 2 above.

Several studies have highlighted the value of palm kernel shell ash in improving the strength of Portland cement concrete, because the addition of SiO2 from palm kernel shell ash to the cement mixture converts calcium hydroxide which is the weak part of Portland cement concrete bond into calcium silicate hydrate. A researcher at the University of Port Harcourt, Nigeria, investigated the effect of calcine conditions (200, 400, 600, 800oC and atmospheric conditions) on the properties of palm kernel shell ash in order to determine its possible use as a pozzolan, or in blended cement. Based on the chemical compositions of the material after calcination, it was proven that the best calcine temperature is 200oC. Again, the high levels of SiO2 and low levels of CaO in the material suggests that it will improve the strength of Portland cement concrete. Palm kernel shell ash has also been used to stabilize poor lateritic soils for road construction. For example, about 4 percent palm kernel shell ash content was found optimal for stabilizing an A-2-6 lateritic soil for road construction in Nigeria.

Geopolymer concrete, which is concrete that uses geopolymer paste as an aggregate binder, is currently being researched as a potential substitute to reduce cement production, and use in the construction industry, because of the contribution of cement production to CO2 emission. Geopolymer paste is produced through polymerization reactions between alkaline activator solutions with silica (Si), and aluminum (Al) materials to form a Si – O – Al polymer bond. Researchers at the Universitas Pelita Harapan and Pradita Institute, Indonesia, examined the effect of using palm kernel shell ash, and rice husk ash in geopolymer concrete mixes on the strength of geopolymer concrete in comparison with the use of palm kernel shell ash, and rice husk ash in Portland cement concrete. They reported an insignificant increment in the geopolymer concrete strength, contrary to the 35 percent increase in strength of the Portland cement concrete.

Palm kernel shell ash has also been fed as a mineral additive to broilers as a partial replacement for a bone meal in their diets. In a study at the Federal University of Technology Owerri, Nigeria, three diets containing graded levels of palm kernel shell ash at 5, 10, and 15 kg/ton of feed respectively to replace equal weights of the bone meal were used to determine the ash effects on performance characteristics of broilers during 28 days (starter phase), and 56 days (finisher phase) of feeding. The ash supplemented birds recorded similar weight gain, feed intake, and feed conversion ratio as the control during the starter phase, and maintained similar growth performance trends at 42 days of the feeding trial. At 56 days, however, the control birds recorded superior growth performance characteristics over the 5 and 15 kg/ton ash supplemented birds. The study, therefore, recommends 10 kg/ton supplementation of broiler starter, and finisher diets with palm kernel shell ash since it elicited better growth performance, and carcass/organ weights.

Conclusion

Palm kernel shell as a major by-product of palm oil production has in recent times become an important renewable biofuel source because of the global concerns about the environmental effects of extensive use of fossil fuel. It is currently exploited for on-plantation energy generation, and also being exported by some industrial-scale palm oil producers in Asia. The material however remains under-exploited in Africa. Since several studies have demonstrated the value of palm kernel shells in biofuel/energy, and concrete production, water purification, and production of top-grade activated charcoal, and ash, there is a need for African palm oil producers to exploit these technologies to improve their revenue from palm oil production. Adoption of these technologies will also create channels for innovative oil palm waste management, and job creation in the region.

Bibliographic references

Andas, J., Rahman, M.L.A., and Yahya, M.S.M. (2017). Preparation and characterization of activated carbon from palm kernel shell. IOP Conf. Series: Materials Science and Engineering 226. doi:10.1088/1757-899X/226/1/012156

Baby, R., Saifullah, B. and Hussein, M.Z. (2019). Palm kernel shell as an effective adsorbent for the treatment of heavy metal contaminated water. Scientific Reports, 9: 18955. https://doi.org/10.1038/s41598-019-55099-6

Dechapanya, W., Rattanahirun, S., and Khamwichit, A. (2020). Syngas production from palm kernel shells with enhanced tar removal using biochar from agricultural residues. Front. Energy Res., 8:157. doi: 10.3389/fenrg.2020.00157

Fuadi, N.A.B., Ibrahim, A.S., Ismail, K.N. (2012). Review study for activated carbon from palm shell used in the treatment of wastewater. Journal Purity Util. React. Environ., 1: 252 – 266.

Gibigaye, M., and Godonou, G.F. (2018). Mixture proportioning for oil palm kernel shell. IntechOpen, http://dx.doi.org/10.5772/intechopen.75601

Hardjasaputra, H., Fernando, I., Indrajaya, J., Cornelia, M., and Rachmansyah (2018). The effect of using palm kernel shell ash and rice husk ash on Geopolymer concrete. MATEC Web of Conferences, 251, 01044 (2018). https://doi.org/10.1051/matecconf/201825101044

Haryati, Z., Loh, S.K., Kong, S., and Bachmann, R.T. (2018). Pilot scale biochar production from palm kernel shell (PKS) in a fixed bed allothermal reactor. Journal of Oil Palm Research,

DOI: https://doi.org/10.21894/jopr.2018.0043

Ikumapayi, O.M., and Akinlabi, E.T. (2018). Composition, characteristics, and socioeconomic benefits of palm kernel shell exploitation- An overview. Journal of Environmental Science and Technology, 11(5): 220 – 232.

Mbada, N.I., Atanda, P.O., Aponbiede, O., Abioye, A.A., Ugbaja, M.I., and Alabi, A.S. (2016). Performance evaluation of the sustainability of carbonized palm kernel shell (PKS) as a veritable alternative to coal and charcoal in solid fuel-fired furnaces. International Journal of Metallurgical Engineering, 5(1): 15 – 20.

Nam, W.L., Phang, X.Y., Su, M.H., Liew, R.K., Ma, N.L., Rosli, M.H.N.B., and Lam, S.S. (2017). Production of bio-fertilizer from microwave vacuum pyrolysis of palm kernel shell for the cultivation of Oyster mushroom (Pleurotus ostreatus). Sci. Total Environ., doi: 10.1016/j.scitotenv.2017.12.108. Epub 2017 Dec 12.

Ogbodo, M.C. (2017). Palm kernel shell ash as a soil stabilizing agent and its optimum calcine temperature. International Journal of Advanced Research and Publication, 1(4): 191 – 193.

Ohanaka, A.U.C. (2016). Physiological responses of broilers to dietary inclusion of palm kernel shell ash. MSc Thesis, Federal University of Technology Owerri, Nigeria.

Onyeagba, B.O., Eze, S.K., and, Madu, O. (2016). Torrefaction of Nigerian palm kernel shell into solid fuel. Science Innovation, 4(3-1): 19 - 23.

Pranolo, S.H., Setyono, P., and Fauzi, M.K. (2020). Life cycle analysis of palm kernel shell gasification for supplying heat to an asphalt mixing plant. Waste Disposal and Sustainable Energy, 2: 55 – 63.

Zafar, S. (2018). Trends in the utilization of palm kernel shells. BioEnergy Consult.